China OEM Ceramic Ball As Catalyst Support Media - Thermal Storage Ball with different Alumina content – Kelley

China OEM Ceramic Ball As Catalyst Support Media - Thermal Storage Ball with different Alumina content – Kelley Detail:

Product Detail

Thermal storage ball is made of kaolin, aluminum oxide, mullite crystals, synthetic aggregates and other materials. According to the two methods of machine pressing and roll forming. The product has low thermal resistance, high density, high temperature resistance, corrosion resistance, high strength, good thermal conductivity, oxidation resistance, strong slag resistance, large thermal conductivity and heat capacity, high heat storage efficiency; good thermal stability and difficult temperature changes Fragmentation and other advantages. The specific surface area can reach 240m2/m3. When in use, many small balls divide the airflow into very small streams. When the airflow passes through the heat storage body, a strong turbulence is formed, which effectively breaks the boundary layer on the surface of the heat storage body. Because of the small diameter of the ball, With small conduction radius, small thermal resistance, high density, and good thermal conductivity, it can meet the requirements of frequent and rapid reversing of the regenerative burner.

This technology uses dual preheating of gas and air to achieve stable ignition even with low calorific value inferior fuels, so that the combustion temperature can quickly reach the requirements of steel rolling for heating billets. At the same time, it is easy to replace and clean, can be reused, and has a long service life.

The regenerator can use the reversal of 20-30 times/h, and the high-temperature flue gas can be discharged after passing through the bed of the regenerator to reduce the flue gas to about 130°C.

The high-temperature coal gas and air flow through the heat storage body in the same path and can be respectively preheated to only about 100℃ lower than the flue gas temperature, and the temperature efficiency is as high as 90% or more.

Because the volume of the heat storage body is very small and the flow capacity of the small pebble bed is strong, even if the resistance increases after ash accumulation, the heat exchange index will not be affected.

Physical Properties

|

Type |

APG Heat Storage Ball |

Heating Furnace Storage Ball |

|

|

Item |

|||

|

Chemical Content |

Al2O3 |

20-30 |

60-65 |

|

Al2O3+ SiO2 |

≥90 |

≥90 |

|

|

Fe2O3 |

≤1 |

≤1.5 |

|

|

Size(mm) |

10-20/12-14 |

16-18/20-25 |

|

|

Thermsl Capacity (J/kg.k) |

≥836 |

≥1000 |

|

|

Thermal Conductivity(w/m.k) |

2.6-2.9 |

||

|

High blast Temperature(°C) |

800 |

1000 |

|

|

Bulk Density (kg/m3) |

1300-1400 |

1500-1600 |

|

|

Refractoriness(°C) |

1550 |

1750 |

|

|

Wear rate(%) |

≤0.1 |

≤0.1 |

|

|

Moh’s Hardness(Scal) |

≥6.5 |

≥6.5 |

|

|

Compressive Strength(N) |

800-1200 |

1800-3200 |

|

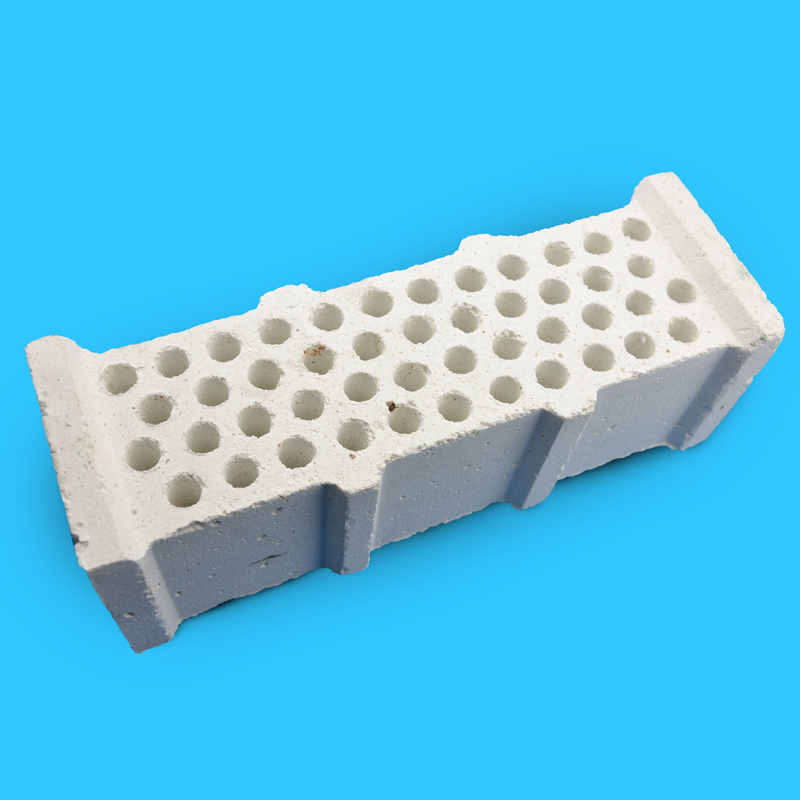

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for China OEM Ceramic Ball As Catalyst Support Media - Thermal Storage Ball with different Alumina content – Kelley, The product will supply to all over the world, such as: Montpellier, Jamaica, Yemen, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.