China Supplier 350y Mellapack - RTO – Heat Exchange Honeycomb Ceramic – Kelley

China Supplier 350y Mellapack - RTO – Heat Exchange Honeycomb Ceramic – Kelley Detail:

Functions

1.Reduce the thermal loss of exhaust gas, and improve the efficiency of fuel to save energy as.

2.Enhance the burning temperature based on theory, improve the atmospheric burning, meet the high temperature of thermal equipment enlarge low calorific value fuel, especially the application range of blast furnaces, improve the efficiency of calorific value fuel and reduce the emissions from low calorific value coal gas.

3.Improve the terms of heat exchange in hearths, increase the output of equipment, enhance the quality of products and cut down on reinvesting in equipment.

4.Reduce the exhaust emission of thermal equipment, alleviate the air pollution and improve the environment.

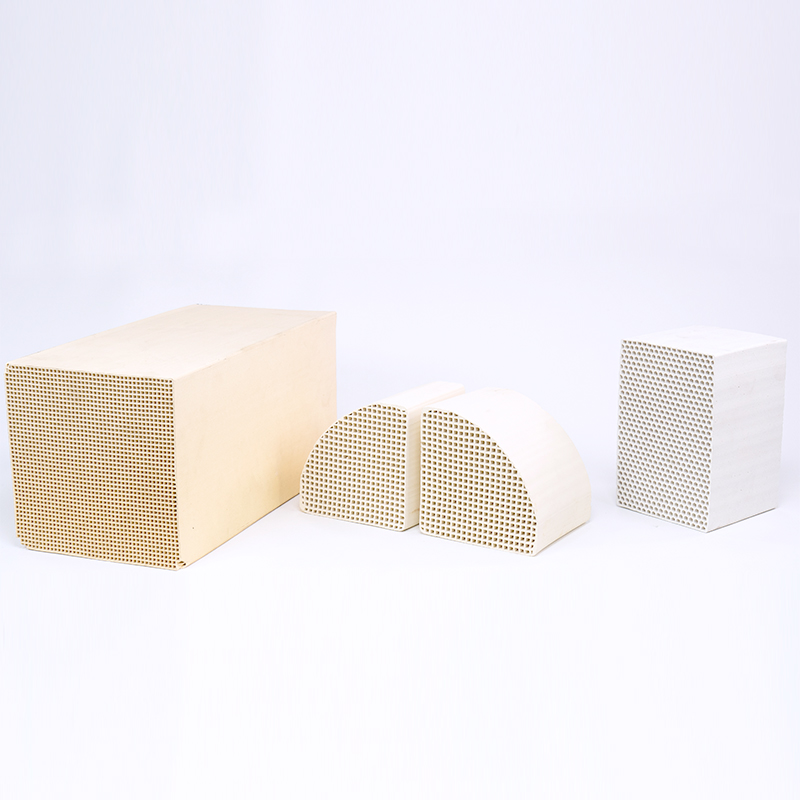

Characteristics

The characteristics of the honeycomb ceramic regenerator are as follow: they have low heat expansion, high specific heat capacity, high specific surface area, low pressure drop, low thermal resistance, good thermal conductivity, thermal shock resistant and much more. So, in metallurgy and chemical industries, it’s used as HTAC, while we combine recycling the heat of the emissions, high efficient combustion with reducing NOx. It becomes a true energy saver and decreases Nox.

Materials: Alumina,Dense Alumina,Cordierite,Dense Cordierite,Mullite,Corundum Mullite and others

Application

Honeycomb ceramic is the key and core component of heat storage high temperature combustion technology (HTAC technology). It has been widely used in various push-steel heating furnaces, walking heating furnaces, heat treatment furnaces, forging furnaces, melting furnaces, ladle/tundish roasters, soaking furnaces, radiant tube burners, and bell-type furnaces in the metallurgical machinery industry. Furnace, blast furnace hot air furnace; various ceramic furnaces and various glass furnaces in the building materials industry; various tubular heating furnaces, cracking furnaces and other industrial furnaces in the petrochemical industry.

Specifications

100x100x100、100x150x150、150x150x150、150x150x300mm and others

Hole count: 25×25、40×40、43×43、50×50、60×60 and others

Dimension

|

Dimension (mm) |

Cells (N×N) |

Cell Density (CPSI) |

Channel Width(mm) |

Inner wall Thickness (mm) |

Free Cross Section (%) |

|

150×150×300 |

20×20 |

11 |

6.00 |

1.35 |

64 |

|

150×150×300 |

25×25 |

18 |

4.90 |

1.00 |

67 |

|

150×150×300 |

32×32 |

33 |

3.70 |

0.90 |

63 |

|

150×150×300 |

40×40 |

46 |

3.00 |

0.70 |

64 |

|

150×150×300 |

43×43 |

50 |

2.80 |

0.65 |

64 |

|

150×150×300 |

50×50 |

72 |

2.40 |

0.60 |

61 |

|

150×150×300 |

59×59 |

100 |

2.10 |

0.43 |

68 |

Chemical Composition

|

Item |

Cordierite |

Mullite |

Alumina Porcelain |

High Alumina Porcelain |

Corundum |

|

Al2O3 |

33 |

65 |

54 |

67 |

72 |

|

SiO2 |

58 |

30 |

39 |

23 |

22 |

|

MgO |

7.5 |

<1 |

3.3 |

1.7 |

<1 |

|

Others |

1.5 |

14 |

3.7 |

8.3 |

5 |

Physical Properties

|

Item |

Cordierite (Porous) |

Mullite |

Alumina Porcelain |

High Alumina Porcelain |

Corundum |

|

| Density(g/cm3) |

1.8 |

2.0 |

1.9 |

2.2 |

2.5 |

|

| Water Absorption (%) |

23 |

18 |

20 |

13 |

12 |

|

| Coefficient of Thermal Expansion(×10-6K-1) (20~800℃) |

≤3.0 |

≤6.0 |

≤6.3 |

≤6.0 |

≤8.0 |

|

| Specific Heat (J/Kg.K) (20~1000℃) |

750-900 |

1100-1300 |

850-1100 |

1000-1300 |

1300-1400 |

|

| Thermal Conductivity(W/m.k) (20~1000℃) |

1.3-1.5 |

1.5-2.3 |

1.0-2.0 |

1.5-2.3 |

5~10 |

|

| Max. Working Temp.(℃) |

1200 |

1400 |

1300 |

1400 |

1650 |

|

| Axial crushing strength (MPa) | Dry |

≥11 |

≥20 |

≥11 |

≥22 |

≥25 |

| Immersion |

≥2.5 |

≥2.5 |

≥2.5 |

≥2.5 |

≥2.5 |

|

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for China Supplier 350y Mellapack - RTO – Heat Exchange Honeycomb Ceramic – Kelley, The product will supply to all over the world, such as: Moscow, Kyrgyzstan, Singapore, Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

We have been looking for a professional and responsible supplier, and now we find it.