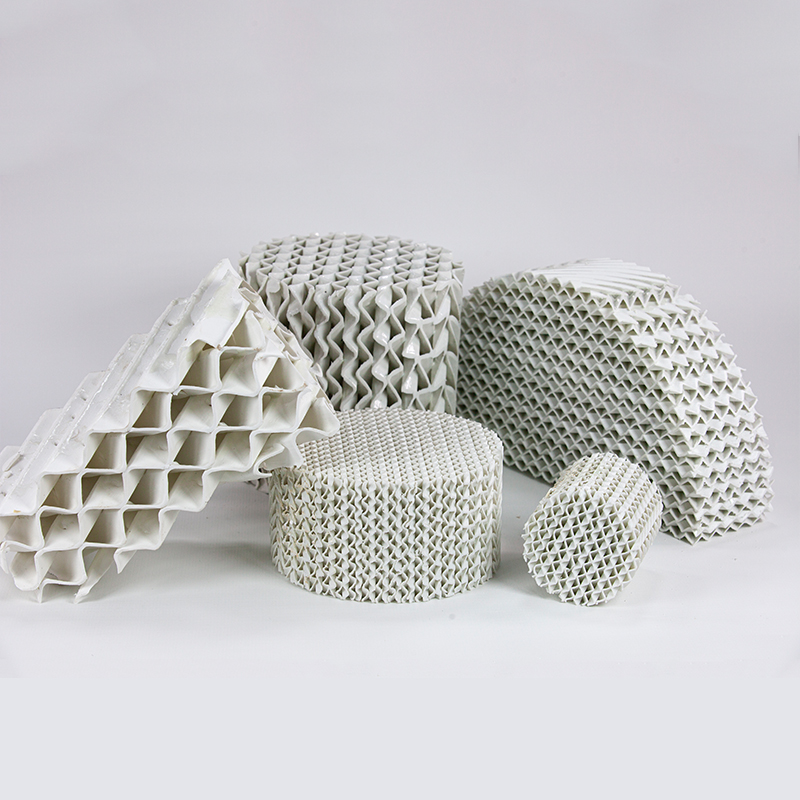

Factory Heat resistance Combined Cermaic Light Packing for scrubber Tower

|

Size

|

X-01 | X-11 | X-12 | X-13 | X-14 |

| Outside diameter(mm) | 220±25 | 220±25 | 220±25 | 220±25 | 220±25 |

| Space(mm) | 20 | 20 | 20 | 20 | 20 |

| Pore size(mm) | 65 | 65 | 65 | 65 | 65 |

| Surface area(m2/m3) | 118 | 128 | 135 | 132 | 148 |

| Free volume(%) | 85 | 75 | 72 | 75 | 73 |

| Bulk Density(kg/m3) | 280 | 320 | 340 | 300 | 348 |

The advantages of using light ceramic packings are as follows:

1. The product has well-developed micropores and strong ability to adhere and adsorb impurities; High gas permeability, well-developed micropores, and good strength. Durable to handling, impact, and air flow. Its apparent porosity is ≥ 15%, and it has strong adhesion and adsorption ability for various impurities in gas, liquid and other process media, with good purification effect.

2. Light product weight, high mechanical strength, and low resistance

The stacking weight of light ceramic filler products is 280-350kg/m3, which is much lower than the stacking density of ordinary regular fillers. The stacking porosity of the product is ≥ 72%, the apparent porosity is ≥ 15%, and the total porosity is over 85%. The mask has the advantages of light weight, small load, low operating resistance, and reduced pressure of the packed tower.

As structured packing, the product has a dry tower resistance of less than 50mm water column and an operating resistance of less than 100mm water column in a naphthalene washing tower with a gas flux of 50000 m3/hour, which makes it less prone to blockage and overcomes the disadvantages of easy breakage and blockage of loose fillers.

3. High mass transfer coefficient, large effective area, and good separation effect

The measurement of the performance of light ceramic fillers by Tianjin University shows that the product has a high mass transfer coefficient, which is 2.2 times that of other fillers. In addition, after the light ceramic filler is filled, only 6 adjacent support legs overlap to form an ineffective area, and the gas-liquid transmission is in the form of “surface” contact. In addition, the light ceramic filler is a microporous honeycomb ceramic with microporous area and spatial droplet area, making the effective area of the filler greater than 99.5%, resulting in separation and purification effects.

4. Light ceramic fillers have strong aging resistance, corrosion resistance, and long service life

The light ceramic filler has good heat resistance, with a fire resistance of up to 1400 ℃, and is resistant to rapid cooling and heating; In addition, the seven hole light ceramic regular filler has excellent acid and alkali resistance, long service life, and is not prone to aging.

5. The all ceramic filler has a novel structure, can be cut, and is easy to fill

The light ceramic filler series regular filler can be cut and assembled into a circle, which is not only convenient for filling, but also allows the entire filling plane to be utilized. Other regular fillers, due to their non cutting nature, inevitably have voids of varying sizes around the tower, resulting in severe wall and groove flow phenomena, which can affect the effectiveness of use to varying degrees.

In summary, the light ceramic packing has successfully solved the contradiction between porosity and specific surface area, which is not easy to block the tower but also has good performance, making it the choice of filler tower users.