Factory source Wearproof Grinding Ball - 99%AL2O3 Inert Alumina Ceramic Ball – Catalyst Support Media – Kelley

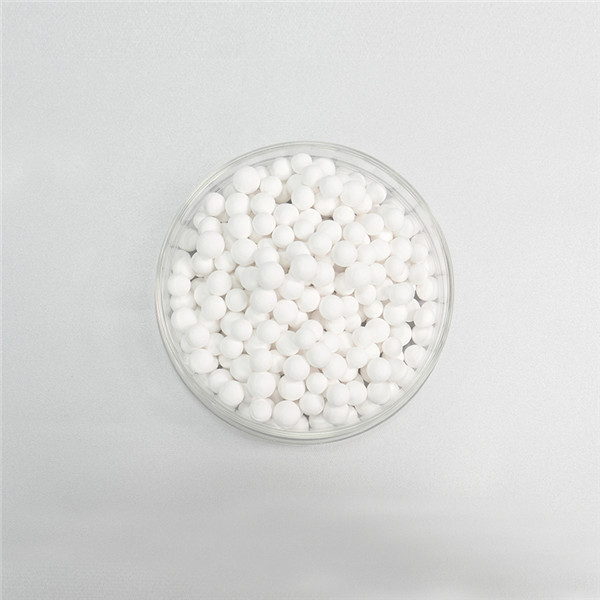

Factory source Wearproof Grinding Ball - 99%AL2O3 Inert Alumina Ceramic Ball – Catalyst Support Media – Kelley Detail:

Application

99% high alumina ceramic balls are widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries as catalyst covering carrier materials and tower packing in reactors. It has high temperature and pressure resistance, low water absorption, stable chemical properties, resistance to acid, alkali and other organic solvents, and can withstand the effects of temperature changes during the production process. Its main function is to increase the distribution point of gas or liquid, support and protect the catalyst with low activity.

Chemical Composition

|

Al2O3 |

Fe2O3 |

MgO |

SiO2 |

Na2O |

TiO2 |

|

>99% |

<0.1% |

<0.5% |

<0.2% |

<0.05% |

<0.05% |

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<4 |

|

Packing density (g/cm3) |

1.9-2.2 |

|

Specific gravity (g/cm3) |

>3.6 |

|

Operation temp.(max) (℃) |

1650 |

|

Apparent porosity (%) |

<1 |

|

Moh’s hardness (scale) |

>9 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

kgf/particle |

KN/particle |

|

|

1/8″ (3mm) |

>40 |

>0.4 |

|

1/4″ (6mm) |

>80 |

>0.8 |

|

1/2″ (13mm) |

>580 |

>5.8 |

|

3/4″ (19mm) |

>900 |

>9.0 |

|

1″ (25mm) |

>1200 |

>12 |

|

1-1/2″(38mm) |

>1800 |

>18 |

|

2″ (50mm) |

>2150 |

>21.5 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

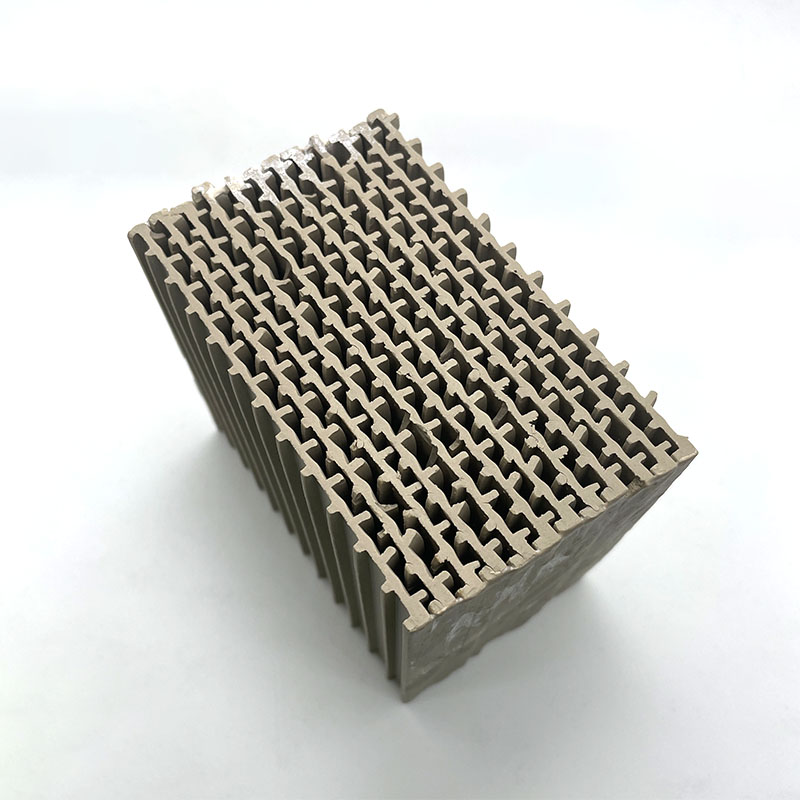

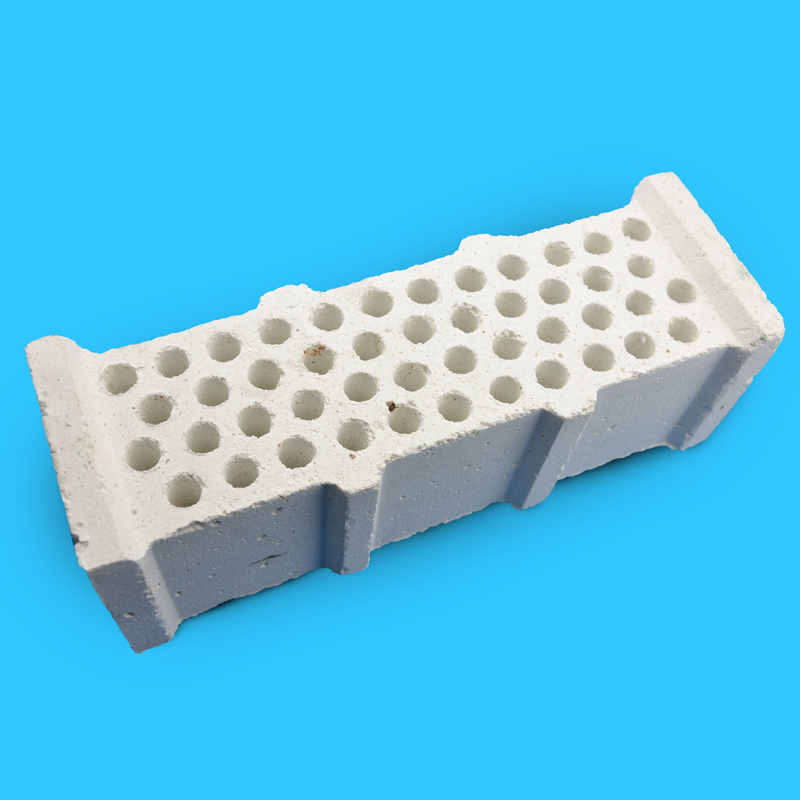

Product detail pictures:

Related Product Guide:

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Factory source Wearproof Grinding Ball - 99%AL2O3 Inert Alumina Ceramic Ball – Catalyst Support Media – Kelley, The product will supply to all over the world, such as: Swaziland, Turkey, Bolivia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.