Fixed Competitive Price Grinding Ceramic Balls - 17% Inert Ceramic Ball – Catalyst Support Media – Kelley

Fixed Competitive Price Grinding Ceramic Balls - 17% Inert Ceramic Ball – Catalyst Support Media – Kelley Detail:

Application

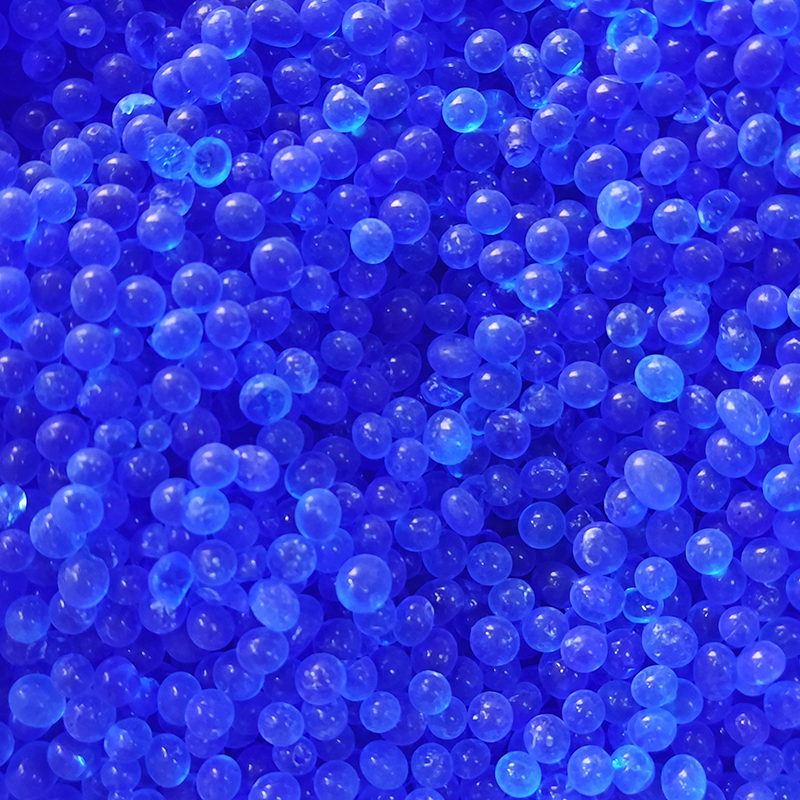

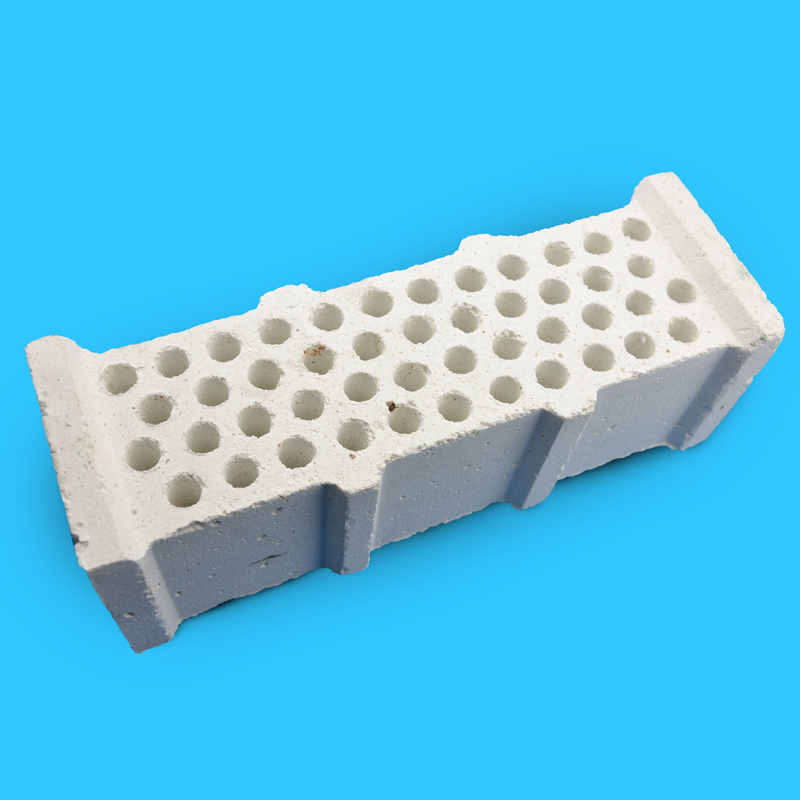

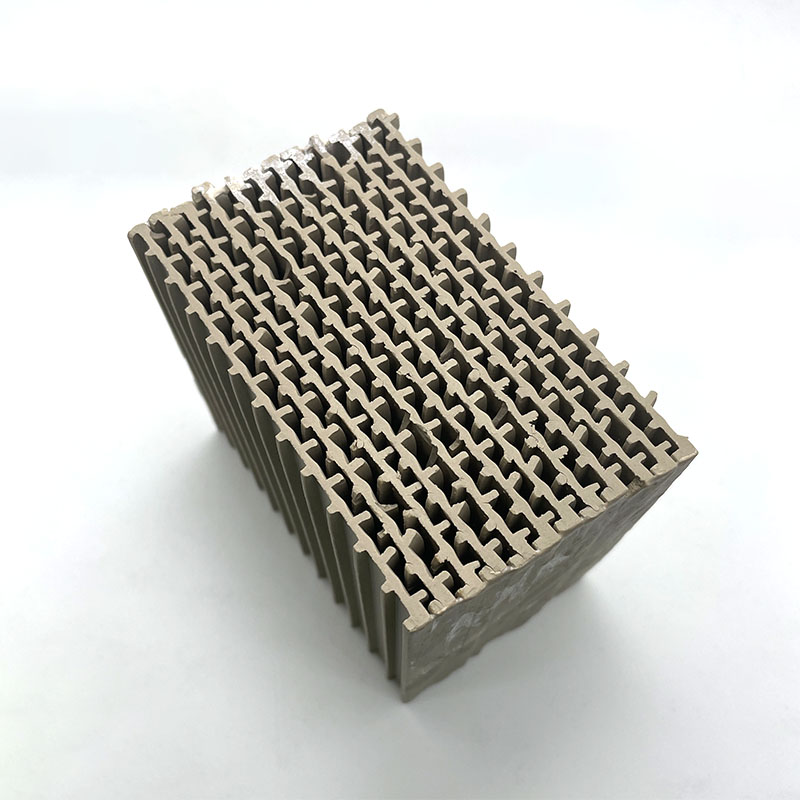

17%AL2O3 Inert Alumina Ceramic Ball widely used in petroleum, chemical, fertilizer, gas and environmental protection industries, as a catalyst in the reactor to cover support material and tower packing.It has a high temperature and high pressure resistance, bibulous rate is low, the characteristics of the chemical performance is stable.Can withstand the erosion of acid, alkali and other organic solvents, and can endure in the production process of temperature changes.Its main function is to increase gas or liquid distribution points, support and protection intensity is not high activity of the catalyst.

Chemical Composition

|

Al2O3+SiO2 |

Al2O3 |

SiO2 |

Fe2O3 |

MgO |

K2O+Na2O+CaO |

Other |

|

> 93% |

> 17% |

60-70% |

<1% |

<0.5% |

<4% |

<1% |

Leach able Fe2O3is less than 0.1%

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<0.5 |

|

Bulk density (KGS/M3) |

1300-1450 |

|

Specific gravity (g/cm3) |

2.3-2.4 |

|

Free volume (%) |

40 |

|

Operation temp.(max) (℃) |

1200 |

|

Moh’s hardness (scale) |

>6.5 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

Crush Strength

|

Size |

Crush strength |

|

|

Kgf/particle |

KN/particle |

|

|

1/8”(3mm) |

>20 |

>0.20 |

|

1/4”(6mm) |

>50 |

>0.50 |

|

3/8”(10mm) |

>85 |

>0.85 |

|

1/2”(13mm) |

>180 |

>1.80 |

|

3/4”(19mm) |

>430 |

>4.30 |

|

1”(25mm) |

>620 |

>6.20 |

|

1-1/2”(38mm) |

>880 |

>8.80 |

|

2”(50mm) |

>1200 |

>12.0 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency revenue team values customers' wants and company communication for Fixed Competitive Price Grinding Ceramic Balls - 17% Inert Ceramic Ball – Catalyst Support Media – Kelley, The product will supply to all over the world, such as: Slovak Republic, Albania, Bogota, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.