Fixed Competitive Price Random Packing - Ceramic Raschig Ring with 1/4″&1/2″& 5/8”&3/4”&1” – Kelley

Fixed Competitive Price Random Packing - Ceramic Raschig Ring with 1/4″&1/2″& 5/8”&3/4”&1” – Kelley Detail:

Application

45%AL2O3 Inert Alumina Ceramic Ball widely used in petroleum, chemical, fertilizer, gas and environmental protection industries, as a catalyst in the reactor to cover support material and tower packing.It has a high temperature and high pressure resistance, bibulous rate is low, the characteristics of the chemical performance is stable.Can withstand the erosion of acid, alkali and other organic solvents, and can endure in the production process of temperature changes.Its main function is to increase gas or liquid distribution points, support and protection intensity is not high of the catalyst.

Chemical Composition

|

Al2O3+SiO2 |

Al2O3 |

SiO2 |

Fe2O3 |

MgO |

K2O+Na2O+CaO |

Other |

|

> 92% |

45% |

47% |

<1% |

<2.5% |

<4% |

<0.5% |

Leach able Fe2O3is less than 0.1%

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<0.5 |

|

Bulk density (g/cm3) |

1.38-1.5 |

|

Specific gravity (g/cm3) |

2.3-2.4 |

|

Free volume (%) |

40 |

|

Operation temp.(max) (℃) |

1250 |

|

Moh’s hardness (scale) |

>6.5 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

Kgf/particle |

KN/particle |

|

|

1/8”(3mm) |

>25 |

>0.25 |

|

1/4”(6mm) |

>60 |

>0.60 |

|

3/8”(10mm) |

>100 |

>1.00 |

|

1/2”(13mm) |

>230 |

>2.30 |

|

3/4”(19mm) |

>500 |

>5.0 |

|

1”(25mm) |

>700 |

>7.00 |

|

1-1/2”(38mm) |

>1000 |

>10.00 |

|

2”(50mm) |

>1300 |

>13.00 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

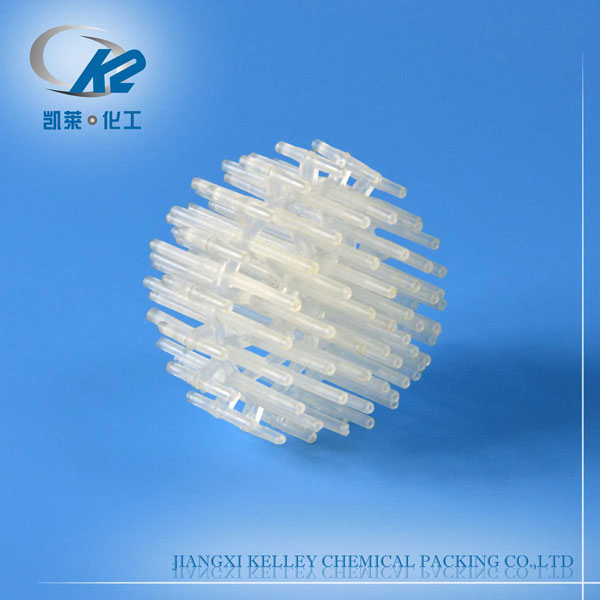

Product detail pictures:

Related Product Guide:

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Fixed Competitive Price Random Packing - Ceramic Raschig Ring with 1/4″&1/2″& 5/8”&3/4”&1” – Kelley, The product will supply to all over the world, such as: Lithuania, Mongolia, Bangkok, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.