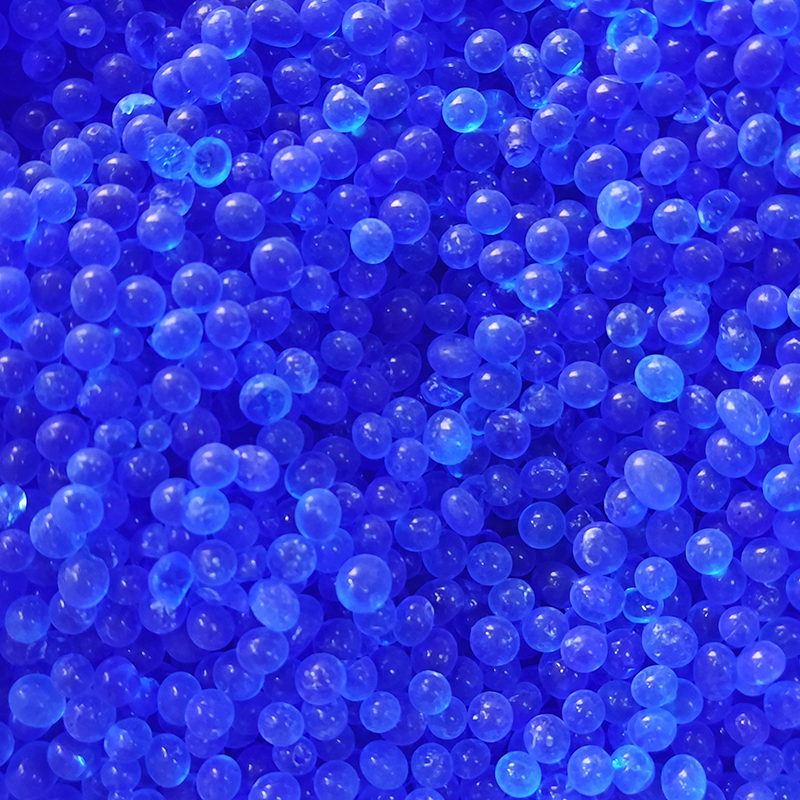

Manufactur standard Imtp For Refinery Tower – Silica Gel Desiccant Manufacturer – Kelley

Manufactur standard Imtp For Refinery Tower – Silica Gel Desiccant Manufacturer – Kelley Detail:

Products description:

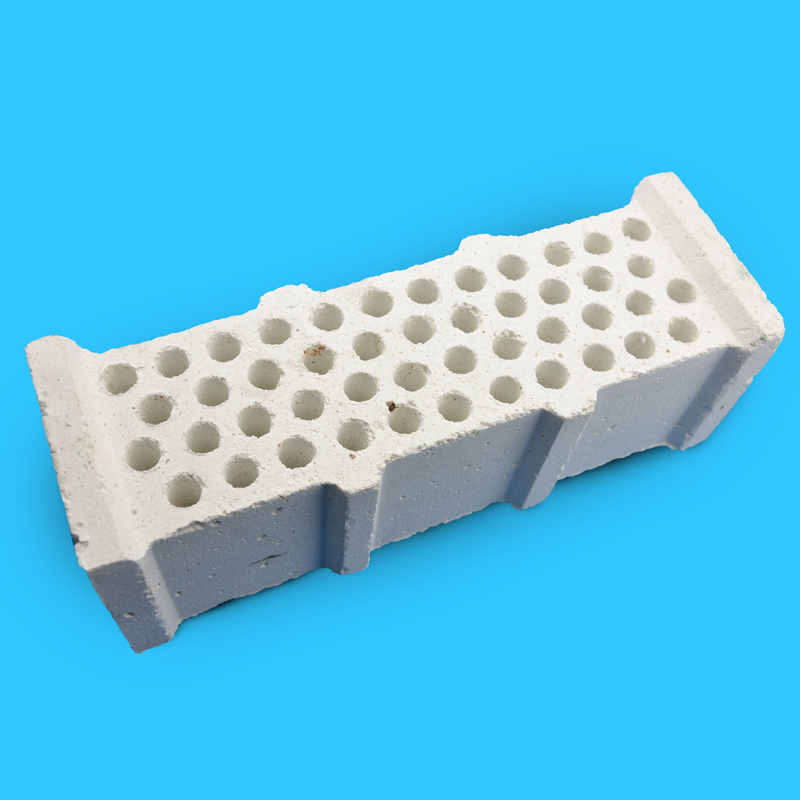

Metal Intalox Saddle was developed by the United States Norton, between the shape of its saddle-shaped ring and between, and the advantages of both. Intalox metal structure in the saddle-shaped packing ring based on the increase of the annular tendon, to avoid overlap and ensure a certain degree of strength and rigidity out of a number of small claws, an increase of gas-liquid agitation, enhanced mass transfer, thus produce a unique performance.

Metal Intalox Saddle is referred to as domestic-shaped locks Intel fill, enjoy a high international reputation. This new type of efficient packing for the new equipment, packed tower, plate tower height lower than 35%, 30% decrease in diameter, or increase the efficiency of 10-30%, 20-60% reduction in pressure loss. Domestic wet instead of dry distillation distillation pilot study showed that 20 percent can reduce the investment. In short, the use of a new type of ring can be increased Intalox yield or low power costs and improve separation efficiency.

Metal Intalox Saddle can be a variety of materials, such as carbon steel, stainless steel 304,304 L, 410,316,316 L, etc. to choose from.

Application:

It is widely used in petrochemical engineering, fertilizer, enviromental protection fields as one of the tower packings. Such as vapor washing tower, purification tower,etc.

Technical Parameter

|

Size (mm) |

Bulk density (304,kg/m3) |

Number (per m3) |

Surface area (m2/m3) |

Free volume (%) |

Dry Packing Factor m-1 |

|

|

15mm |

16.5*10.6*0.25 |

223 |

324110 |

275 |

97.2 |

300.2 |

|

15mm |

16.5*10.6*0.3 |

263 |

324110 |

275 |

96.7 |

304.9 |

|

25mm |

25.9*12.6*0.25 |

163 |

127180 |

415 |

4.8 |

489.2 |

|

25mm |

25.9*12.6*0.3 |

192 |

127180 |

344 |

95.5 |

393.2 |

|

25mm |

25.9*12.6*0.4 |

266 |

127180 |

199 |

96.6 |

221.0 |

|

40mm |

35.4*18.8*0.25 |

124 |

51180 |

151 |

98.4 |

158.3 |

|

40mm |

35.4*18.8*0.3 |

146 |

51180 |

151 |

98.1 |

159.7 |

|

40mm |

35.4*18.8*0.4 |

203 |

51180 |

151 |

97.4 |

163.2 |

|

50mm |

48.5*28.6*0.3 |

95 |

15550 |

97 |

98.8 |

101.0 |

|

50mm |

48.5*28.6*0.4 |

132 |

15550 |

97 |

98.3 |

102.5 |

|

50mm |

48.5*28.6*0.5 |

169 |

15550 |

97 |

97.9 |

103.9 |

|

60mm |

67*37*0.4 |

113 |

9000 |

84 |

98.6 |

87.3 |

|

60mm |

67*37*0.5 |

145 |

9000 |

84 |

98.2 |

88.4 |

|

70mm |

76.5*42.5*0.4 |

83 |

4690 |

61 |

99.0 |

62.9 |

|

70mm |

76.5*42.5*0.4 |

106 |

4690 |

61 |

98.7 |

63.5 |

Product detail pictures:

Related Product Guide:

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of "quality first, customer supreme" for Manufactur standard Imtp For Refinery Tower – Silica Gel Desiccant Manufacturer – Kelley, The product will supply to all over the world, such as: Bangalore, Holland, Jordan, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products and solutions have been exported to more than 15 countries in the world and have been widely used by customers.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.