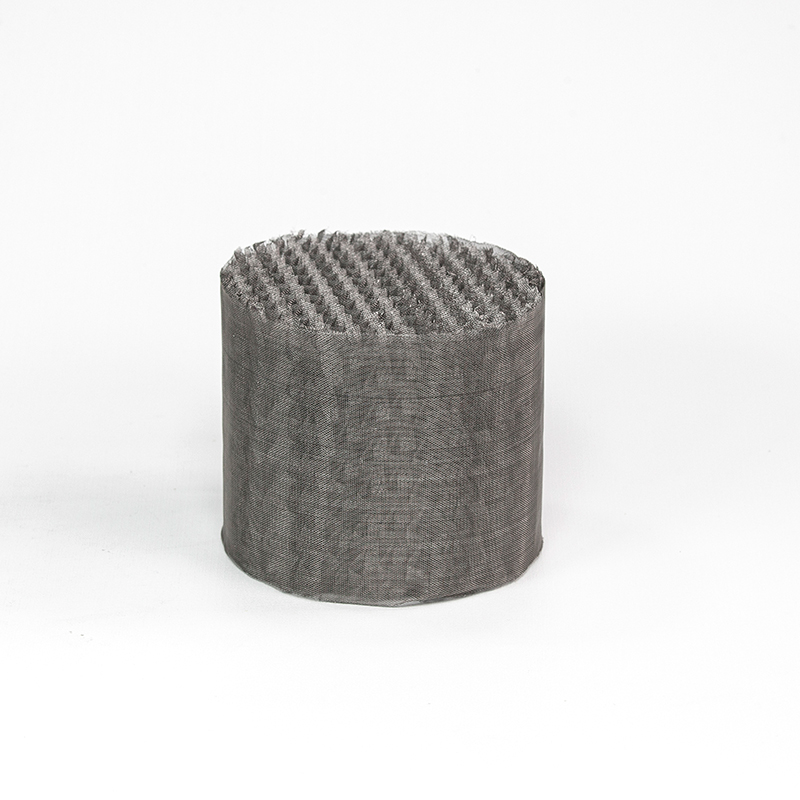

Metal Wire Gauzed Packing with SS304 / SS316

The main advantage of metal wire gauze structured packings:

1. The pieces are placed neatly and the open space between the peaks and valleys is large, and the airflow resistance is small;

2. The direction of the channel between the corrugations is frequently changed, and the airflow sliding is aggravated;

3. The mesh interweaves between the film and the disk and between the disk to promote the continuous redistribution of the liquid;

4. The wire mesh is fine, the liquid can form a stable film on the mesh surface, even if the spray density of the liquid is small, it is easy to reach complete moisture;

5. The number of theoretical plates is high, the flux is large, the pressure drops, and the low load performance is good. The number of theoretical plates is added with the decrease of the gas load, and there is almost no low load limit; the operation flexibility is large; the expansion effect is unclear;

Material

Metal wire gauze packing is available in a wide range of materials, include stainless steels, 304, 316, 316L, Carbon steels. Aluminium, copper bronze etc. Further materials available on request.

Application

It is applied to vacuum distillation for difficult separation and thermal material,also it is applied to atmospheric distillation and absorption process, pressure operation, petrochemical,fertilizer,etc.

Fine chemical, flavours factory, isomer separation. The separation of thermally sensitive materials, testing tower and the improvement of tower.

Technical Date

|

Model |

Peak highness (mm) |

Specific area (m2/m3) |

Theoretical plate (p/m) |

Void volume (%) |

Pressure drop (Mpa/m) |

F-factor (kg/m) |

|

700Y |

4.3 |

700 |

8-10 |

87 |

4.5-6.5X10-4 |

1.3-2.4 |

|

500Y |

6.3 |

500 |

4.5-5.5 |

95 |

3X10-4 |

2 |