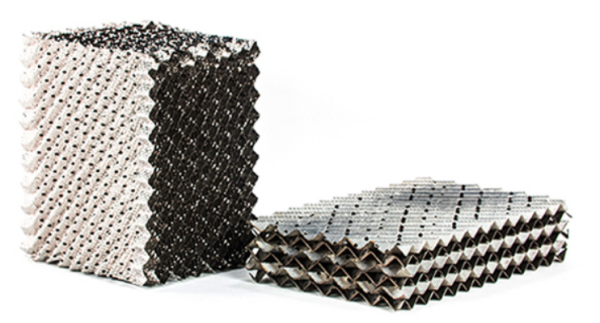

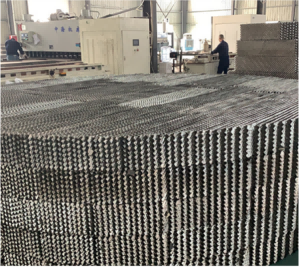

250Y structured packing is an anti-blocking and durable product. It adopts gas-liquid flow and contact method and is divided into two types with directional air deflection and no air deflection. According to different geometric structures, it can also be divided into corrugated packing and orifice plate. Corrugated packing and 250Y metal orifice corrugated structured packing. It has a large specific surface area, is easy to install, and has a good effect in transforming plate towers. It is an ideal choice for industries such as chemical industry and environmental protection. 250Y structured packing adopts special flow control technology, which can improve the uniformity of gas or liquid, reduce diffusion loss and improve heat exchange efficiency. It adopts a high-precision manufacturing process, which can have a higher degree of dispersion, and its anti-blocking performance is also very strong, and maintenance and replacement are also very simple. It is an ideal choice for chemical, environmental protection and other industries.

250y structured packing 304 can be said to be a good choice in oil refining, petrochemical, fine chemical and pharmaceutical industries. It has the characteristics of small resistance, uniform gas-liquid distribution, high efficiency, and large flux, and can meet many different applications such as negative pressure, normal pressure, and pressurized operation. Its corrugated packing is a disc-shaped packing composed of many corrugated thin plates. It has the characteristics of gas-liquid two-phase heat transfer, mass transfer contact surface, surface pressurized pattern, and enhanced packing wettability, which can meet the requirements of public working conditions. . The use of 250y structured packing 304 can greatly increase efficiency and meet the needs of oil refining, petrochemical, fine chemical, pharmaceutical and other industries.

Post time: Apr-01-2023