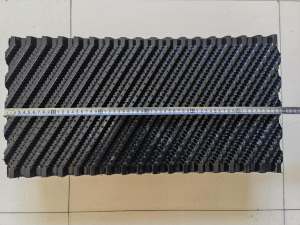

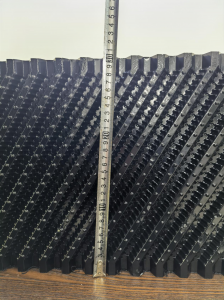

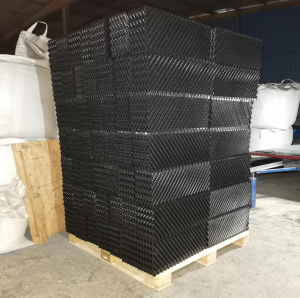

Plastic fill packing is used in cooling tower, most of customers will choose PVC as raw material for their fill packing, but this time our valued customer choose ABS as raw material, due to special using condition which has special request for temperature.

The role of plastic fill packing in cooling towers mainly includes the following aspects:

- Increase heat dissipation: Plastic water-spraying fillers increase the heat dissipation efficiency of water by increasing the contact area and contact time between cooling water and air.

- Extend cooling water residence time: The fillers can make cooling water stay in the tower for a longer time, thereby improving heat exchange efficiency.

- Increase heat exchange area: The design of the fillers helps to form a larger water vapor contact area, thereby increasing heat exchange.Uniform water distribution:

- The water-spraying fillers ensure that water is evenly distributed in the cooling tower, which helps to achieve more efficient heat exchange.

- Maintain water distribution system: The fillers maintain the state of water splashing or forming water film in the cooling tower, enhance evaporation and heat transfer process, and thus quickly reduce water temperature.

Application scenarios of fill packing as below:

Water-spraying filler is suitable for a variety of cooling tower applications, such as air conditioning cooling system, refrigeration series, electric furnace, injection molding, leather making, power generation, steam turbine, aluminum profile processing, air compressor, industrial water cooling, etc.

Post time: Nov-05-2024