Activated alumina, as an efficient adsorbent, has a wide range of applications in the removal of TBC (p-tert-butylcatechol) from styrene.

1.Adsorption principle:

1) Porosity: activated alumina has a porous structure which provides a large surface area and can effectively adsorb TBC from styrene.

2) High hygroscopicity: the high hygroscopicity of activated alumina enables it to adsorb both water and other organic matter, which helps to improve the adsorption efficiency.

2. Adsorption effect

1) Experimental studies: studies have shown that activated alumina performs well in adsorption of TBC from styrene. After about 3 hours of immersion treatment, the content of TBC has been significantly reduced; after about 12 hours of immersion treatment, the content of TBC has been reduced to a level that does not affect the polymerization conversion rate.

(2) Polymerization performance: The content of cis-1,4 structure of styrene after adsorption treatment is basically unaffected during polymerization, but the molecular mass distribution will be broadened.

3.Specific application:

Styrene production: activated alumina is used as an adsorbent in the production and purification of styrene to remove TBC from it in order to improve product quality and stability.

Catalyst protection: Activated alumina can also be used as a catalyst carrier to protect the catalyst from impurities such as TBC and prolong the service life of the catalyst.

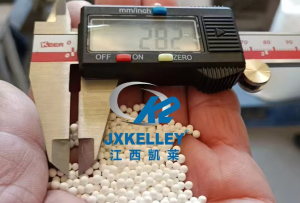

Recently, our VIP customer purchased 16 tons of activated alumina from us for removing TBC from styrene, the following pictures are for your reference:

Post time: Dec-06-2024