Recently, the demand for RTO honeycomb ceramic regenerators in the market is relatively hot. Gloria has also received inquiries from customers in Hunan, Qiqihar, Botou and other places. This time, we introduce the RTO honeycomb ceramic regenerators required by Hunan customers. body for use in regenerative furnaces. Hunan customers have reached cooperation with Jiangxi Gloria by strictly inspecting the company's qualifications, product quality, after-sales service, production scale, price and other factors. Judging from the further development of the current RTO equipment technology, the first is to reduce emissions, improve the burner design and

Recently, the demand for RTO honeycomb ceramic regenerators in the market is relatively hot. Gloria has also received inquiries from customers in Hunan, Qiqihar, Botou and other places. This time, we introduce the RTO honeycomb ceramic regenerators required by Hunan customers. body for use in regenerative furnaces. Hunan customers have reached cooperation with Jiangxi Gloria by strictly inspecting the company's qualifications, product quality, after-sales service, production scale, price and other factors. Judging from the further development of the current RTO equipment technology, the first is to reduce emissions, improve the burner design and combustion process, and control the combustion temperature.

Electric heating is used instead of oil/gas fuel to avoid secondary combustion caused by adding auxiliary fuel and high temperature. Pollution. The second is to study how to gas velocity, develop heat accumulators, reduce equipment volume and reduce investment costs. Improve the initial distribution of the gas, the utilization rate of the regenerator and the heat transfer effect; improve the on-off valve to prolong its service life; in order to further develop the automatic detection and control of various parameters in the device. In addition, numerical calculations and computer simulations of RTO equipment can be used to understand the operational behavior of the process and optimize the design of the equipment, and can in some ways replace the intermediate testing of RTO for cost savings.

RTO treatment technology is suitable for the purification treatment of high-concentration organic waste gas, paint waste gas, and malodorous waste gas (exhaust gas concentration above 500 mg/L). It is suitable for frequent changes in exhaust gas composition or components contained in exhaust gas (such as mercury, tin, zinc and other metal vapors). The catalyst is easily deactivated due to the presence of halogenated hydrocarbons and other corrosive organic gases (gases such as phosphorus, phosphide, arsenic, etc.) that poison or reduce catalyst activity. Although catalytic combustion has technical advantages compared to regenerative combustion treatment technology, catalytic combustion is not suitable for exhaust gases containing metal vapors and halogens because it is prone to catalyst poisoning.

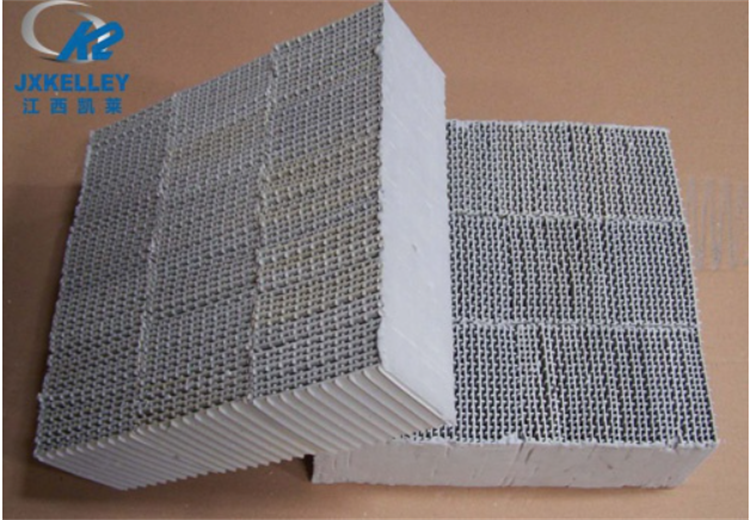

The RTO honeycomb ceramic regenerator has the advantages of large area, fast heat transfer, small airflow resistance, shallow heat penetration depth and high thermal efficiency. There are square holes, round holes, hexagonal holes and other hole types and various wall shapes such as plane, inclined plane, single slot and double slot. It has the advantages of high refractoriness, high softening temperature under load, good slag resistance, good thermal shock stability, fast thermal conductivity, good erosion resistance, large bulk volume, and large heat capacity. The catalytic combustion of CO and HC compounds further recovers the waste heat and reduces the emission of polluting gases.

Post time: Oct-08-2022