The NaOH absorption SO2 packed tower is a common gas absorption equipment, which is often used in the flue gas desulfurization process. Its main principle is to spray NaOH solution on the wire mesh corrugated packing, absorb acid gases such as SO2 and react with NaOH to form corresponding salts, so as to achieve the purpose of purifying flue gas.

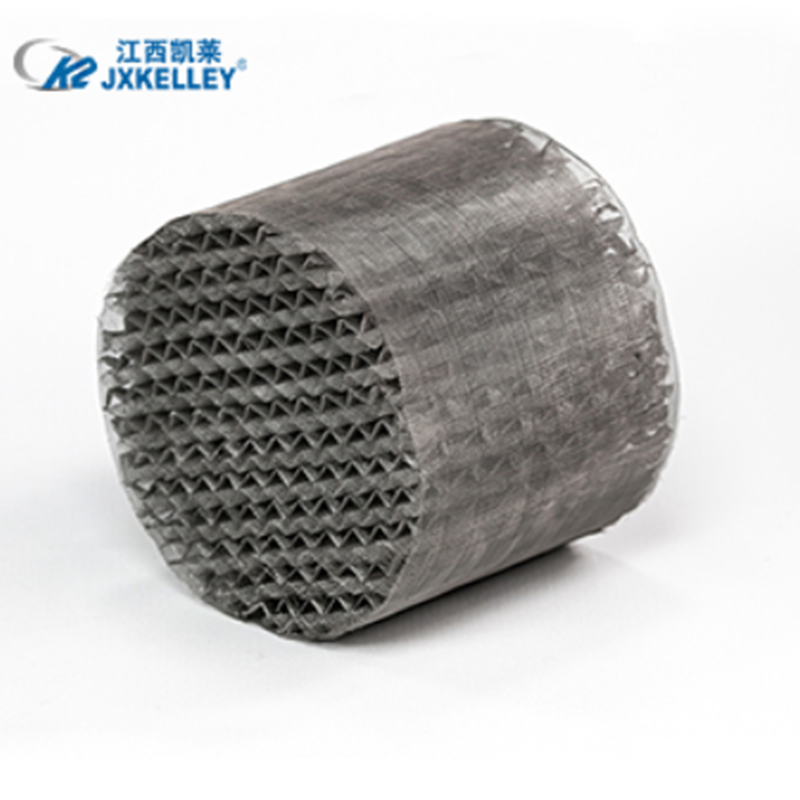

The packed tower is usually composed of corrugated wire mesh packing layer, liquid distributor, air inlet, air outlet, liquid discharge port, discharge port and other parts. The metal mesh corrugated packing layer is a solid packing filled in the packed tower, and its function is to increase the contact area and increase the reaction efficiency. The liquid distributor is a device that sprays NaOH solution evenly on the wire mesh corrugated packing. The air inlet is used to introduce flue gas containing acid gases such as SO2, while the gas outlet is used to discharge the purified flue gas. The liquid outlet is used to discharge the NaOH solution that has absorbed SO2, while the discharge port is used to discharge the purified flue gas and unreacted gas.

In the packed tower, the NaOH solution will contact and absorb acid gases such as SO2 in the flue gas, and react to generate corresponding salts. In this process, factors such as the concentration of NaOH solution, the amount of spraying, and temperature will affect the absorption efficiency. Therefore, in practical applications, it is necessary to adjust the operating parameters of the packed tower according to the specific process requirements and flue gas components.

In addition, the packed tower also requires discharge treatment to ensure that the purified flue gas and discharged liquid meet environmental standards. Usually, the NaOH solution will be collected into the lower liquid pool, and can only be discharged after being neutralized and precipitated.

In short, the NaOH absorption SO2 packing tower is an important gas purification equipment. By spraying NaOH solution on the corrugated wire mesh packing, SO2 and other acidic gases are absorbed and react with NaOH to form salts, so as to achieve the purpose of purifying flue gas. . In practical application, it is necessary to adjust the operating parameters of the packed tower according to the specific process requirements and flue gas components, and perform emission treatment to meet environmental protection requirements.

Post time: Jun-01-2023