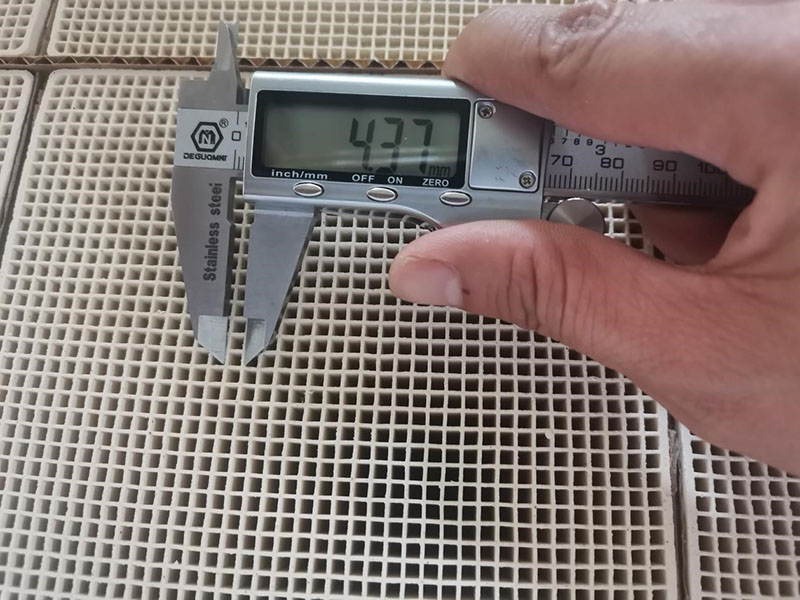

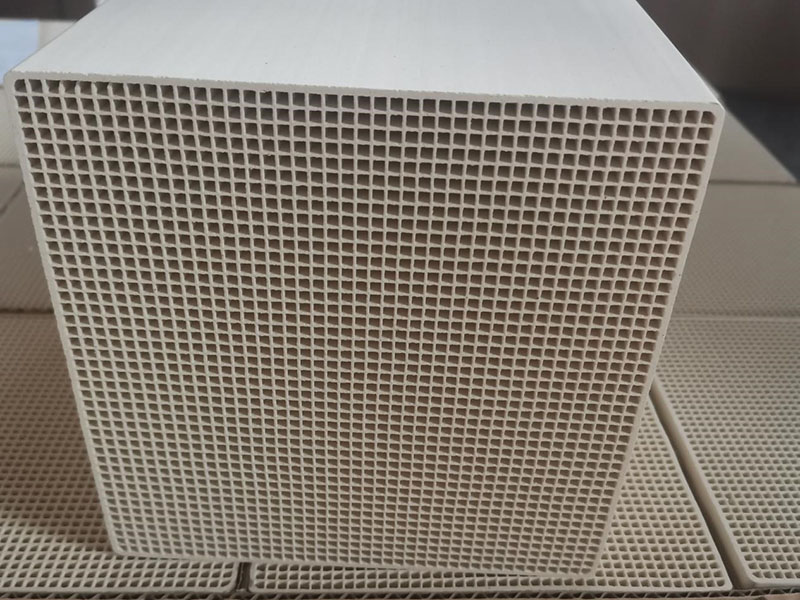

April, it is our honor to supply mullite honeycomb ceramic for our Middle East customer, which need size 150x150x300mm with 50x50cells & 43x43cells & 40x40cells.

It only took us less than one month from order enter to prepare raw materials to mass production and shipping. The efficiency is very fast and the product quality control is perfect. We will never let down the trust and support of our customers in our JXKELLEY company.

Regenerative Thermal Oxidizer/Incinerator (Regenerative Thermal Oxidizer, RTO for short) is an energy-saving and environmentally friendly device used to treat medium and low concentration volatile organic waste gas. The honeycomb ceramic regenerator is one of the core components inside the RTO device: the basic principle of RTO is that combustible organic waste gas undergoes a thermal oxidation reaction at 760 to 1000 degrees Celsius to generate CO2 and water. The exhaust gas is first heated to close to the thermal oxidation temperature by the ceramic regenerator, and then enters the combustion chamber for thermal oxidation. The temperature of the oxidized gas increases, and the organic matter is basically converted into CO2 and water. The purified gas passes through the ceramic regenerator at the other end, the temperature drops, and is discharged after reaching the emission standard.

During the heat exchange process of the high-performance honeycomb ceramic regenerator, the greater the product of the mass density of the regenerator and its own specific heat capacity, the stronger the heat storage capacity of the regenerator and the greater the heat release. In addition, frequent Characteristics such as reversing cycle, long service life, and large heat exchange area per unit volume. Only by combining these parameters can the best choice of heat storage and heat exchange technology be completed. Frequent reversal also affects the service life of the honeycomb regenerator and reversing equipment. The heat storage body has the advantages of small pressure loss, large specific surface area, and fast heat transfer speed. Theoretically, regenerative combustion systems using high-performance honeycomb regenerators are easier to maintain during operation and have higher heat recovery efficiency. Honeycomb heat storage body can have strong adaptability and long service life.

As a new type of heat storage technology, Rto honeycomb ceramic regenerator has good thermal stability, heat capacity and heat transfer efficiency, and can meet the heat storage needs in different fields. It has broad application prospects in industry, medical care, agriculture, aviation and other fields.

Post time: Apr-30-2024