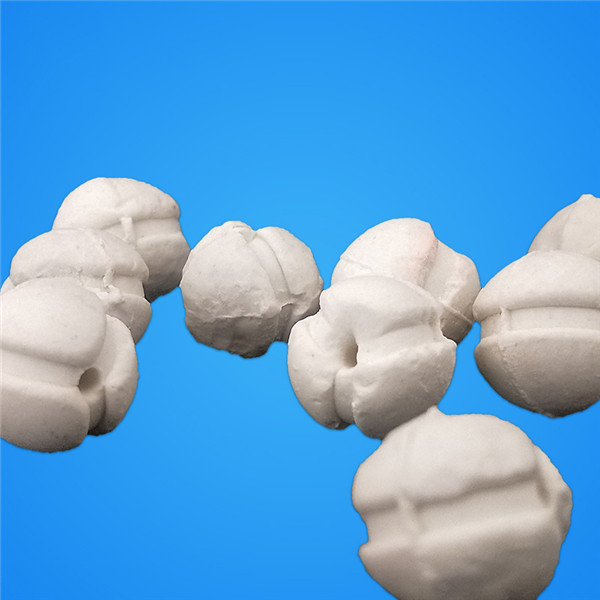

OEM Customized Grinding Ball Mill - Porous Ceramic Ball Manufacturer with different size – Kelley

OEM Customized Grinding Ball Mill - Porous Ceramic Ball Manufacturer with different size – Kelley Detail:

Application

Porous ceramic ball is a new product developed on the basis of the inert alumina ceramic ball. It takes the diameter of the ball as the axis to open the hole. It not only has certain mechanical strength, chemical stability and thermal stability, but also increases the specific surface area. And the void ratio, thereby increasing the dispersion and flux of the material, and reducing the resistance of the system. It can be widely used in petroleum, chemical and natural gas industries to replace inert alumina ceramic balls as catalyst covering support fillers.

Physical Properties

|

Type |

Feldspar | Feldspar- Molai | Molai Stone | Molai- Corundum | Corundum | |||||

|

Item |

||||||||||

|

Chemical Content |

Al2O3 |

20-30 |

30-45 |

45-70 |

70-90 |

≥90 |

||||

|

Al2O3+ SiO2 |

≥90 |

|||||||||

|

Fe2O3 |

≤1 |

|||||||||

| Water Adsorption (%) |

≤5 |

|||||||||

| Acid Resistance (%) |

≥98 |

|||||||||

| Alkaki Resistance (%) |

≥80 |

≥82 |

≥85 |

≥90 |

≥95 |

|||||

| Operation Temperature(°C) |

≥1300 |

≥1400 |

≥1500 |

≥1600 |

≥1700 |

|||||

|

Crushing Strength (N/Piece) |

Φ3mm |

≥400 |

≥420 |

≥440 |

≥480 |

≥500 |

||||

|

Φ6mm |

≥480 |

≥520 |

≥600 |

≥620 |

≥650 |

|||||

|

Φ8mm |

≥600 |

≥700 |

≥800 |

≥900 |

≥1000 |

|||||

|

Φ10mm |

≥1000 |

≥1100 |

≥1300 |

≥1500 |

≥1800 |

|||||

|

Φ13mm |

≥1500 |

≥1600 |

≥1800 |

≥2300 |

≥2600 |

|||||

|

Φ16mm |

≥1800 |

≥2000 |

≥2300 |

≥2800 |

≥3200 |

|||||

|

Φ20mm |

≥2500 |

≥2800 |

≥3200 |

≥3600 |

≥4000 |

|||||

|

Φ25mm |

≥3000 |

≥3200 |

≥3500 |

≥4000 |

≥4500 |

|||||

|

Φ30mm |

≥4000 |

≥4500 |

≥5000 |

≥5500 |

≥6000 |

|||||

|

Φ38mm |

≥6000 |

≥6500 |

≥7000 |

≥8500 |

≥10000 |

|||||

|

Φ50mm |

≥8000 |

≥8500 |

≥9000 |

≥10000 |

≥12000 |

|||||

|

Φ75mm |

≥10000 |

≥11000 |

≥12000 |

≥14000 |

≥15000 |

|||||

| Bulk Density (kg/m3) |

1100-1200 |

1200-1300 |

1300-1400 |

1400-1550 |

≥1550 |

|||||

Size and Tolerance(mm)

|

Diameter |

6 /8 /10 |

13 /16 /20 /25 |

30 /38 /50 |

60 /75 |

|

Tolerance of diameter |

±1.0 |

±1.5 |

±2.0 |

±3.0 |

|

Pore diameter |

2-3 |

3-5 |

5-8 |

8-10 |

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for OEM Customized Grinding Ball Mill - Porous Ceramic Ball Manufacturer with different size – Kelley, The product will supply to all over the world, such as: Rotterdam, America, Uruguay, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!