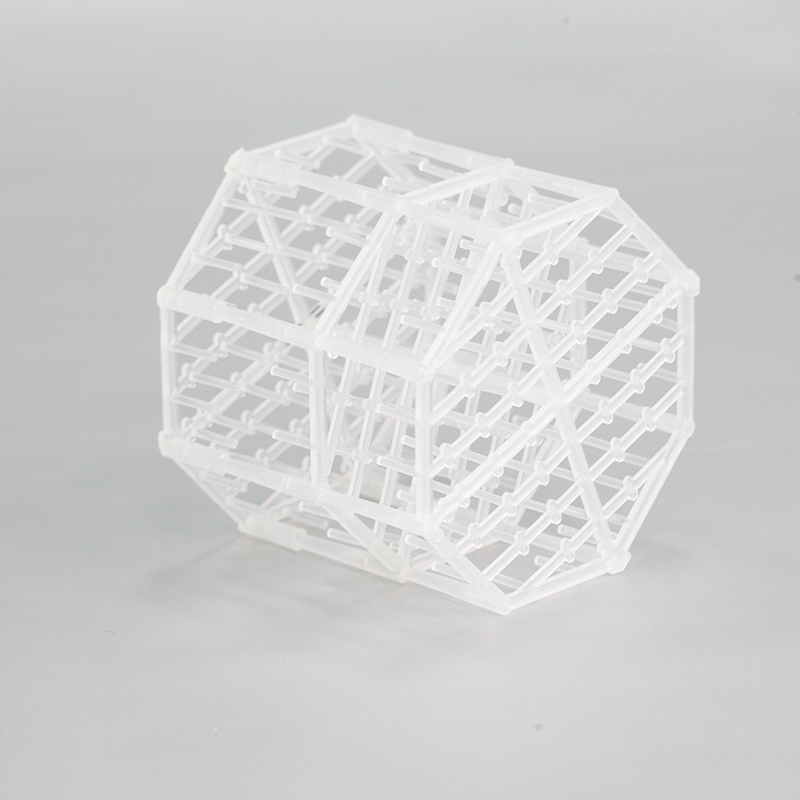

OEM/ODM Manufacturer Plastic Pall Ring Tower Packing - Plastic Q-pack With PP / PE/CPVC – Kelley

OEM/ODM Manufacturer Plastic Pall Ring Tower Packing - Plastic Q-pack With PP / PE/CPVC – Kelley Detail:

Technical Data Sheet

|

Product Name |

Plastic Q-pack |

||||

|

Material |

PP,PE,PVC,CPVC,PVDF ,etc | ||||

|

Life Span |

>3 years |

||||

|

Size mm |

Drip several |

Void Volume % |

Packing Number pieces/ m3 |

Packing Density Kg/m3 |

Dry Packing Factor m-1 |

|

82.5*95 |

388 |

96.3 |

1165 |

33.7 |

23 |

|

Feature |

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer. | ||||

|

Advantage |

1. Their special structure make it has big flux, low pressure drop, good anti-impaction capability.2. Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. | ||||

|

Application |

These various plastic tower packing are widely used in petroleum and chemical,alkali chloride,gas and environmental protection industries with max. temperature of 150°. | ||||

Physical & Chemical properties

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) ,polyvinyiidene fluoride (PVDF)and Polytetrafluoroethylene(PTFE) .The temperature in media ranges from 60 Degree C to 280 Degree C.

| Performace/Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

| Density(g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

| Operation Temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

| Chemical Corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

| Compression Strength(Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for OEM/ODM Manufacturer Plastic Pall Ring Tower Packing - Plastic Q-pack With PP / PE/CPVC – Kelley, The product will supply to all over the world, such as: Colombia, Saudi Arabia, Buenos Aires, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

A good manufacturers, we have cooperated twice, good quality and good service attitude.