OEM/ODM Supplier Inert Ceramic Ball For Catalyst Support - Porous Ceramic Ball Manufacturer with different size – Kelley

OEM/ODM Supplier Inert Ceramic Ball For Catalyst Support - Porous Ceramic Ball Manufacturer with different size – Kelley Detail:

Application

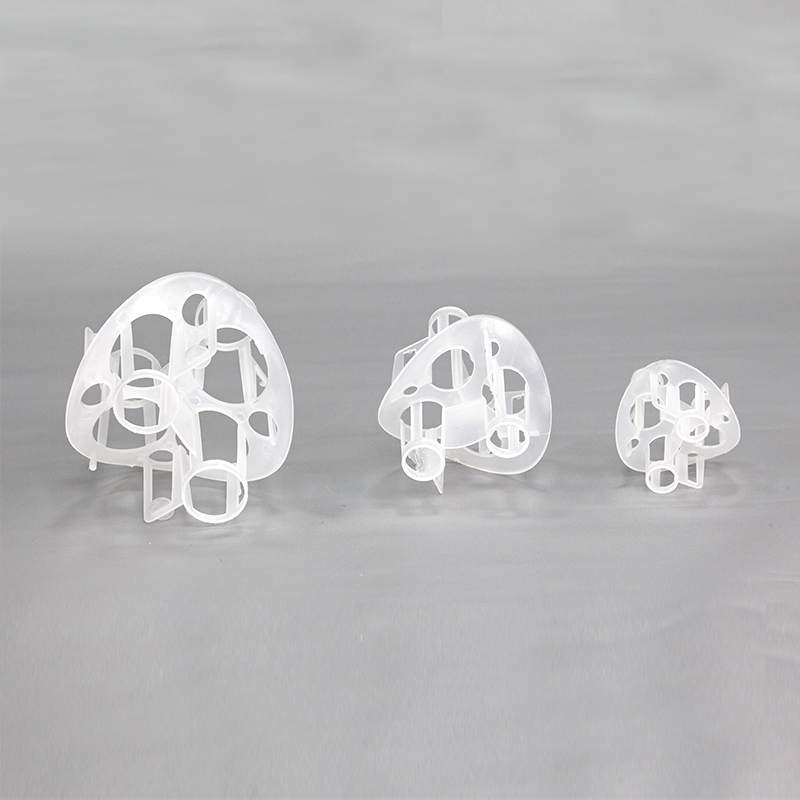

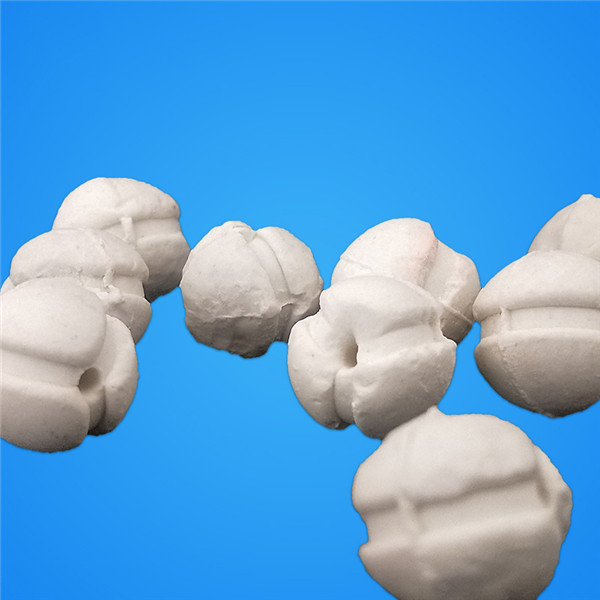

Porous ceramic ball is a new product developed on the basis of the inert alumina ceramic ball. It takes the diameter of the ball as the axis to open the hole. It not only has certain mechanical strength, chemical stability and thermal stability, but also increases the specific surface area. And the void ratio, thereby increasing the dispersion and flux of the material, and reducing the resistance of the system. It can be widely used in petroleum, chemical and natural gas industries to replace inert alumina ceramic balls as catalyst covering support fillers.

Physical Properties

|

Type |

Feldspar | Feldspar- Molai | Molai Stone | Molai- Corundum | Corundum | |||||

|

Item |

||||||||||

|

Chemical Content |

Al2O3 |

20-30 |

30-45 |

45-70 |

70-90 |

≥90 |

||||

|

Al2O3+ SiO2 |

≥90 |

|||||||||

|

Fe2O3 |

≤1 |

|||||||||

| Water Adsorption (%) |

≤5 |

|||||||||

| Acid Resistance (%) |

≥98 |

|||||||||

| Alkaki Resistance (%) |

≥80 |

≥82 |

≥85 |

≥90 |

≥95 |

|||||

| Operation Temperature(°C) |

≥1300 |

≥1400 |

≥1500 |

≥1600 |

≥1700 |

|||||

|

Crushing Strength (N/Piece) |

Φ3mm |

≥400 |

≥420 |

≥440 |

≥480 |

≥500 |

||||

|

Φ6mm |

≥480 |

≥520 |

≥600 |

≥620 |

≥650 |

|||||

|

Φ8mm |

≥600 |

≥700 |

≥800 |

≥900 |

≥1000 |

|||||

|

Φ10mm |

≥1000 |

≥1100 |

≥1300 |

≥1500 |

≥1800 |

|||||

|

Φ13mm |

≥1500 |

≥1600 |

≥1800 |

≥2300 |

≥2600 |

|||||

|

Φ16mm |

≥1800 |

≥2000 |

≥2300 |

≥2800 |

≥3200 |

|||||

|

Φ20mm |

≥2500 |

≥2800 |

≥3200 |

≥3600 |

≥4000 |

|||||

|

Φ25mm |

≥3000 |

≥3200 |

≥3500 |

≥4000 |

≥4500 |

|||||

|

Φ30mm |

≥4000 |

≥4500 |

≥5000 |

≥5500 |

≥6000 |

|||||

|

Φ38mm |

≥6000 |

≥6500 |

≥7000 |

≥8500 |

≥10000 |

|||||

|

Φ50mm |

≥8000 |

≥8500 |

≥9000 |

≥10000 |

≥12000 |

|||||

|

Φ75mm |

≥10000 |

≥11000 |

≥12000 |

≥14000 |

≥15000 |

|||||

| Bulk Density (kg/m3) |

1100-1200 |

1200-1300 |

1300-1400 |

1400-1550 |

≥1550 |

|||||

Size and Tolerance(mm)

|

Diameter |

6 /8 /10 |

13 /16 /20 /25 |

30 /38 /50 |

60 /75 |

|

Tolerance of diameter |

±1.0 |

±1.5 |

±2.0 |

±3.0 |

|

Pore diameter |

2-3 |

3-5 |

5-8 |

8-10 |

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for OEM/ODM Supplier Inert Ceramic Ball For Catalyst Support - Porous Ceramic Ball Manufacturer with different size – Kelley, The product will supply to all over the world, such as: Miami, Bolivia, Milan, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!