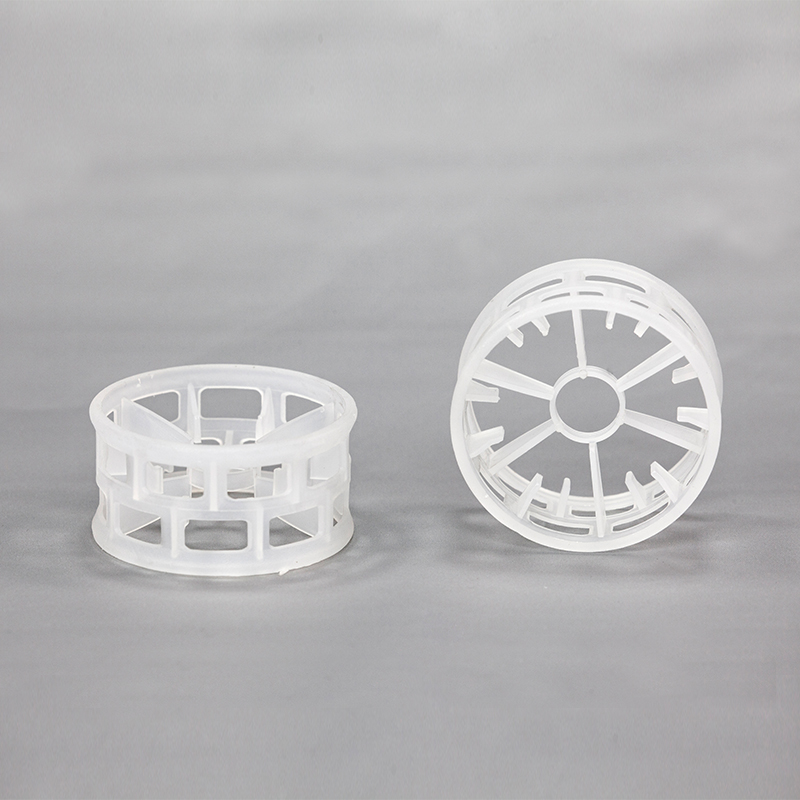

Plastic Beta Ring With PP / PE/CPVC

Plastic Beta Ring has the characteristics of high porosity, low pressure drop, mass unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, and high heat and mass transfer efficiency.

Plastic Beta Ring packing is a very efficient random packing for chemical industry. Used for water vapor cooling tower, absorption tower and stripping device in separation device.

Technical Data Sheet

|

Product Name |

Plastic Beta Ring |

||

|

Material |

PP,PE,PVC,CPVC,RPP, PVDF and etc. |

||

|

Life Span |

>3 years |

||

|

Product name |

Diameter (mm/Inch) |

Void Volume % |

Packing Density Kg/m3 |

|

Beta Ring |

25(1”) |

94 |

53kg/m³(3.3lb/ft³) |

|

Beta Ring |

50(2”) |

94 |

54kg/m³(3.4lb/ft³) |

|

Beta Ring |

76(3”) |

96 |

38kg/m³(2.4lb/ft³) |

|

Feature |

1.Low aspect ratio increases capacity and reduces pressure drop. The preferred vertical orientation of the packing axes allows free gas flow through the packed bed.

2.Lower pressure drop than Pall rings and saddles. |

||

|

Advantage |

Open structure and preferred vertical orientation inhibits fouling by allowing solids to be more easily flushed through the bed by the liquid.Low liquid hold-up minimizes column inventory and liquid residence time.

Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. |

||

|

Application |

These various plastic tower packing are widely used in petroleum and chemical,alkali chloride,gas and environmental protection industries with max. temperature of 280°. | ||