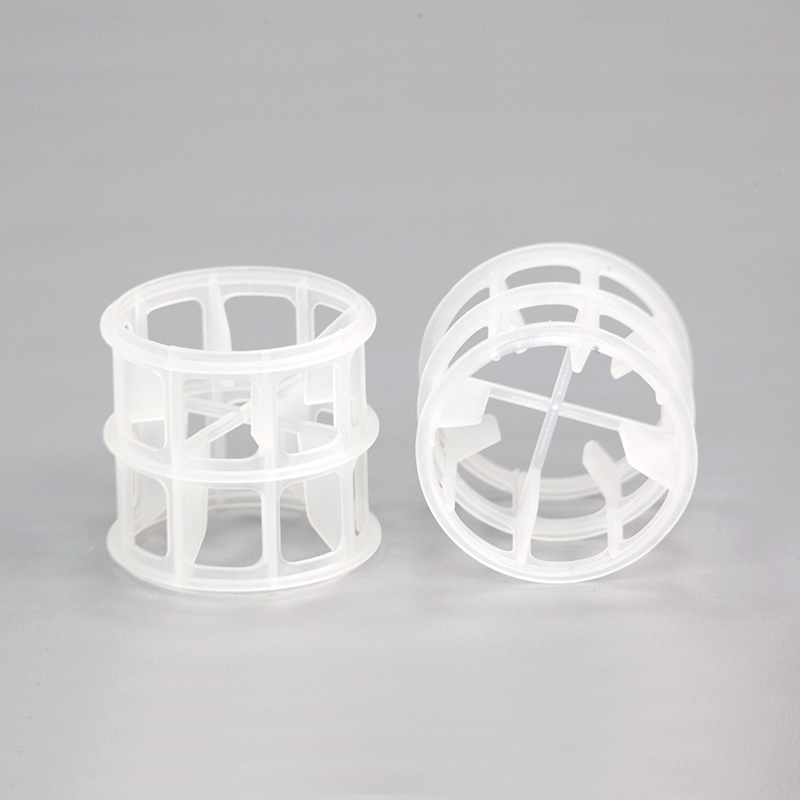

Plastic Hiflow Ring With PP / PE/CPVC

Material

Our Factory assure all tower packing made from 100% Virgin Material.

Technical Data Sheet

|

Product Name |

Plastic Hiflow Ring |

|||

|

Material |

PP,PE,PVC,CPVC,PVDF ,etc | |||

|

Life Span |

>3 years |

|||

|

Size |

Surface Area m2/m3 |

Void Volume % |

Packing Density Kg/m3 |

|

|

Inch |

mm |

|||

|

1/2” |

16 |

260 |

91 |

80 |

|

1” |

25 |

210 |

92 |

79 |

|

1-1/2” |

38 |

140 |

94 |

58 |

|

2” |

50 |

100 |

94 |

54 |

|

3-1/2” |

90 |

73 |

96 |

33 |

|

Feature |

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer. | |||

|

Advantage |

1. Their special structure make it has big flux, low pressure drop, good anti-impaction capability.2. Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. | |||

|

Application |

These various plastic tower packing are widely used in petroleum and chemical,alkali chloride,gas and environmental protection industries with max. temperature of 150°. | |||

Physical & Chemical properties

| Performace/Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

| Density (g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

| Operation Temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

| Chemical Corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

| Compression Strength (Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |