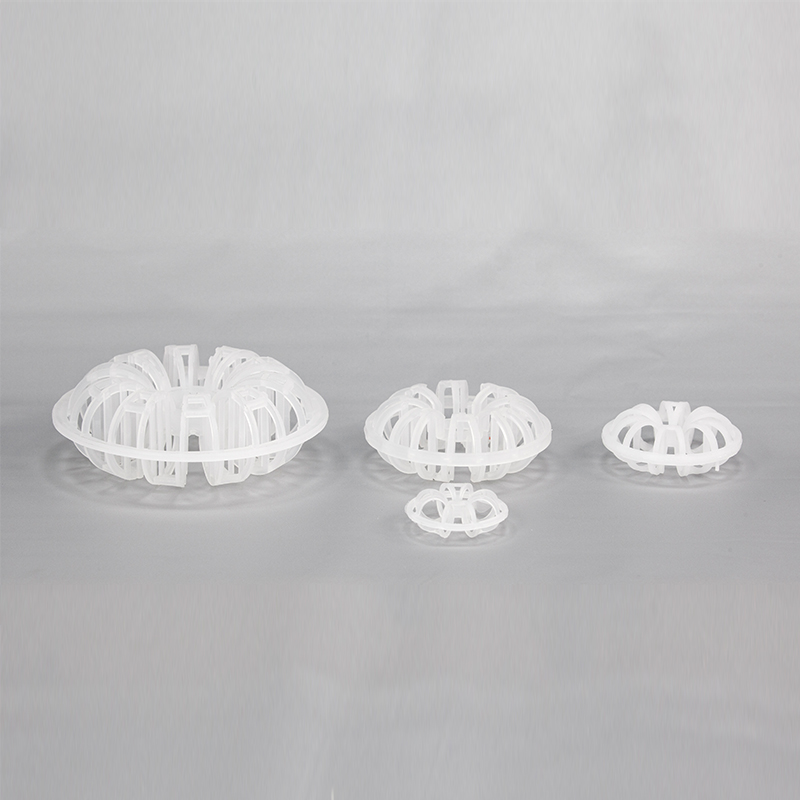

Plastic Rosette Ring With PP / PE/CPVC

Technical Data Sheet

|

Product Name |

Plastic Rosette Ring |

||||

|

Material |

PP,PE,PVC,CPVC,RPP,PVDF and ETFE etc |

||||

|

Life Span |

>3 years |

||||

|

Size mm |

Surface Area m2/m3 |

Void Volume % |

Packing Number pieces/ m3 |

Packing Density Kg/m3 |

Dry Packing Factor m-1 |

|

25*9*(1.5*2) (5 ring) |

269 |

82 |

170000 |

85 |

488 |

|

47*19*(3*3) (9 ring) |

185 |

88 |

32500 |

58 |

271 |

|

51*19*(3*3) (9 ring) |

180 |

89 |

25000 |

57 |

255 |

|

59*19*(3*3) (12 ring) |

127 |

89 |

17500 |

48 |

213 |

|

73*27.5*(3*4) (12 ring) |

94 |

90 |

8000 |

50 |

180 |

|

95*37*(3*6) (18 ring) |

98 |

92 |

3900 |

52 |

129 |

|

145*37(3*6) (20 ring) |

65 |

95 |

1100 |

46 |

76 |

|

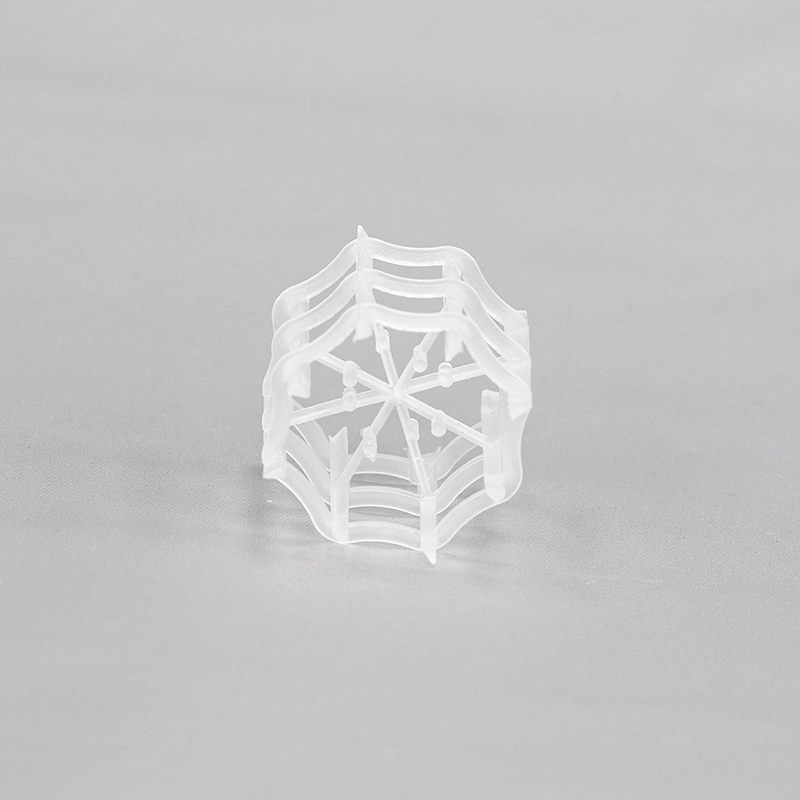

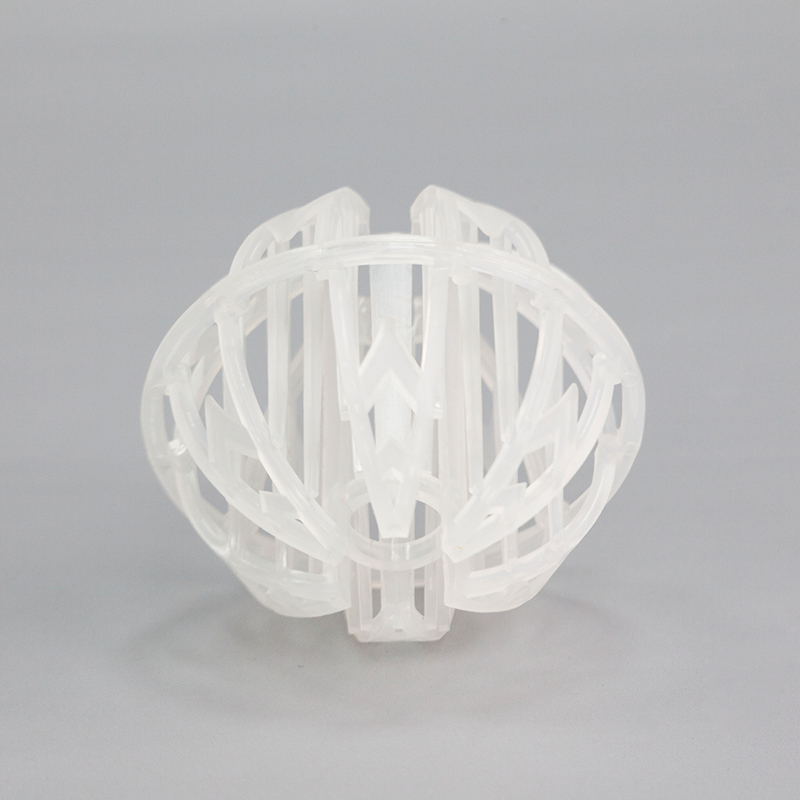

Feature |

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer. | ||||

|

Advantage |

1. Their special structure make it has big flux, low pressure drop, good anti-impaction capability.

2. Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. |

||||

|

Application |

Gas absorption, Acidic gases deabsorption system, Washing, Fertilizer production。These various plastic tower packing are widely used in petroleum and chemical,alkali chloride,gas and environmental protection industries with max. temperature of 280°. | ||||