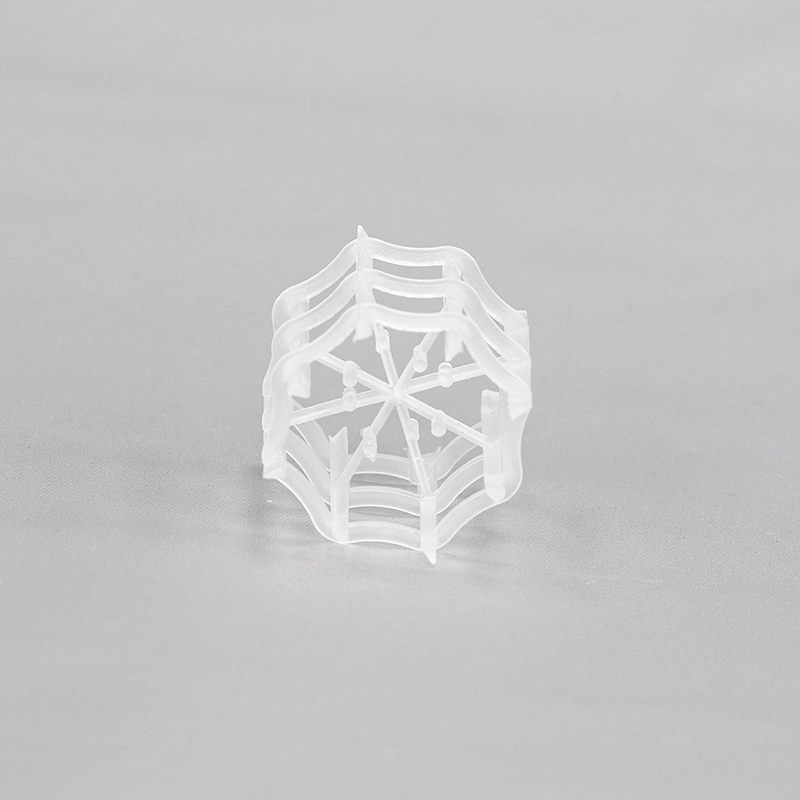

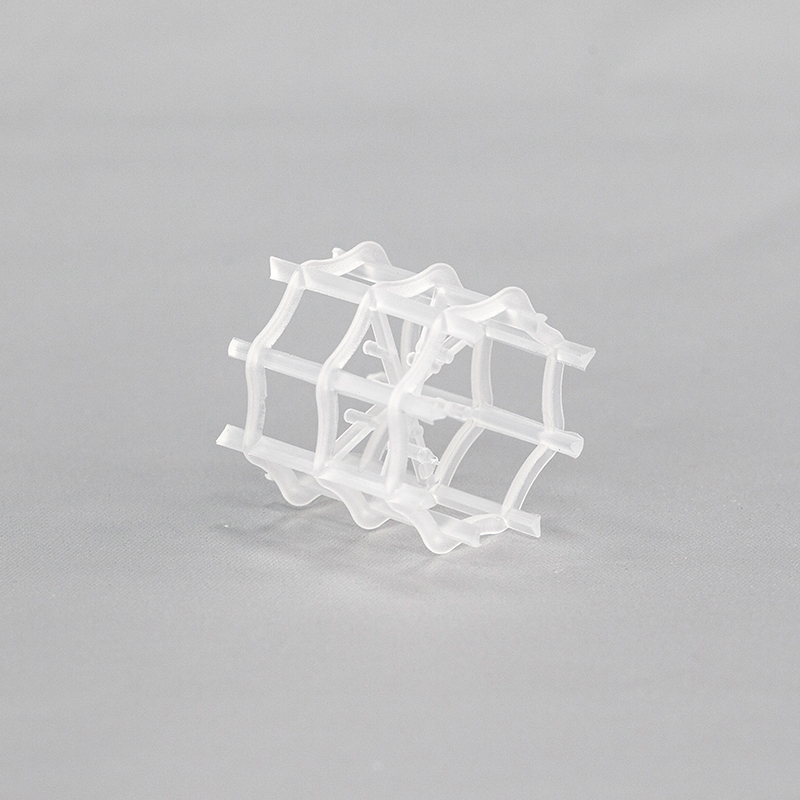

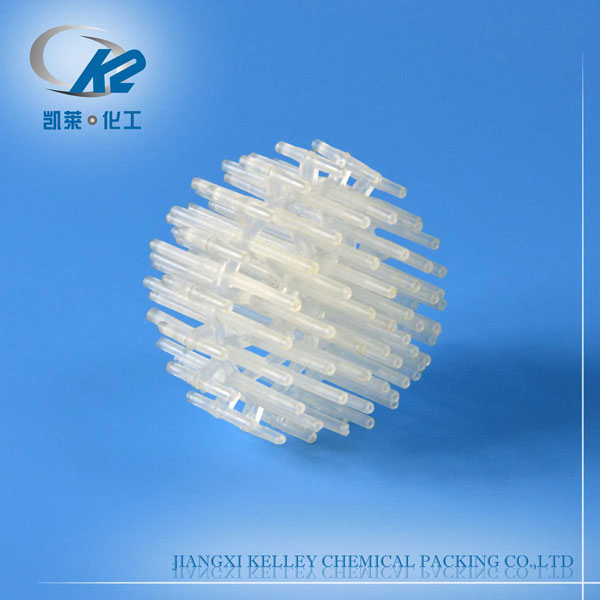

Plastic VSP Ring With PP / PE/CPVC

VSP Ring has rational symmetry, excellent inner structure and large free space .Compared with Pall ring, its flux effiency is increase 15-30% , its pressure drop is reduce 20-30%. it is recognized the excellent random packing in tower packing.

Technical Data Sheet

|

Product Name |

Plastic VSP Ring (Plastic mella ring ) |

||||

|

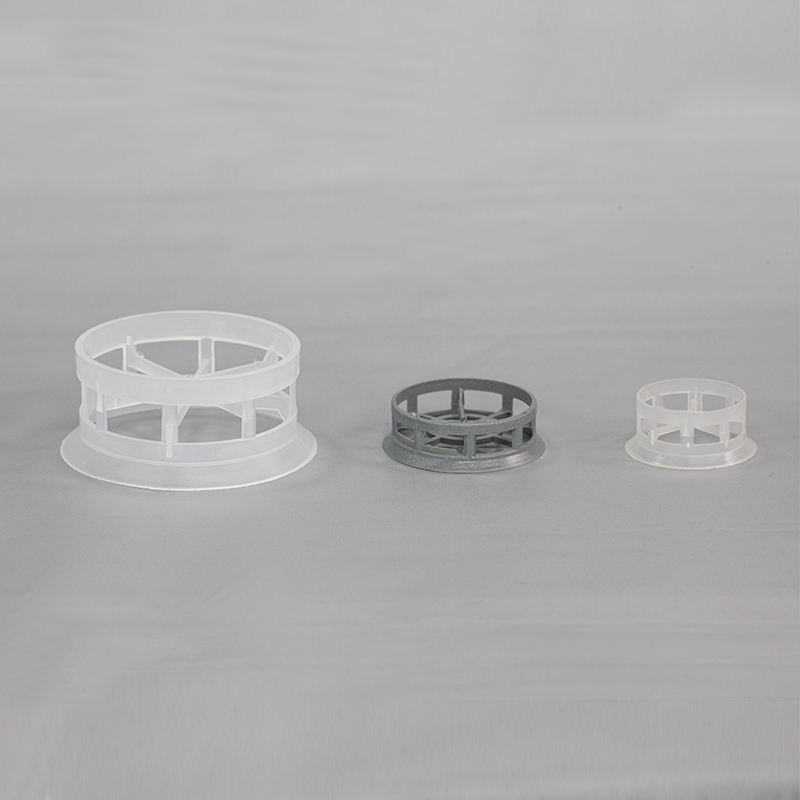

Material |

PP,PE,PVC,CPVC,PVDF ,etc | ||||

|

Life Span |

>3 years |

||||

|

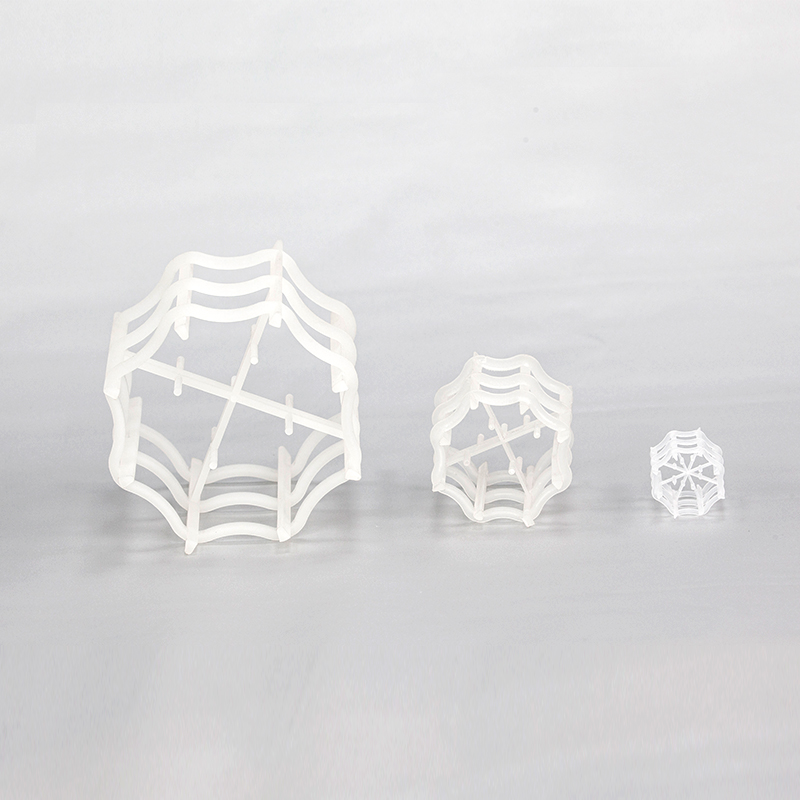

Size |

Surface Area m2/m3 |

Void Volume % |

Packing Number pieces/ m3 |

Packing Density Kg/m3 |

|

|

Inch |

mm |

|

|

|

|

|

1” |

25 |

185 |

93 |

55000 |

60 |

|

1-1/2” |

38 |

138 |

94 |

16000 |

58 |

|

2” |

50 |

121 |

95 |

5500 |

45 |

|

3-1/2” |

90 |

40 |

97 |

1180 |

30 |

|

Feature |

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer. | ||||

|

Advantage |

1.Their special structure make it has big flux, low pressure drop, good anti-impaction capability.

2. Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. |

||||

|

Application |

These various plastic tower packing are widely used in petroleum and chemical,alkali chloride,gas and environmental protection industries with max. temperature of 280°. | ||||