Quality Inspection for Wear-Resistant Grinding Balls for Wet Ball Mills

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Quality Inspection for Wear-Resistant Grinding Balls for Wet Ball Mills, Our firm is dedicated to offering customers with substantial and secure top quality items at competitive cost, earning every customer contented with our services.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for China Steel Balls and Grind The Ball, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which might be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Application

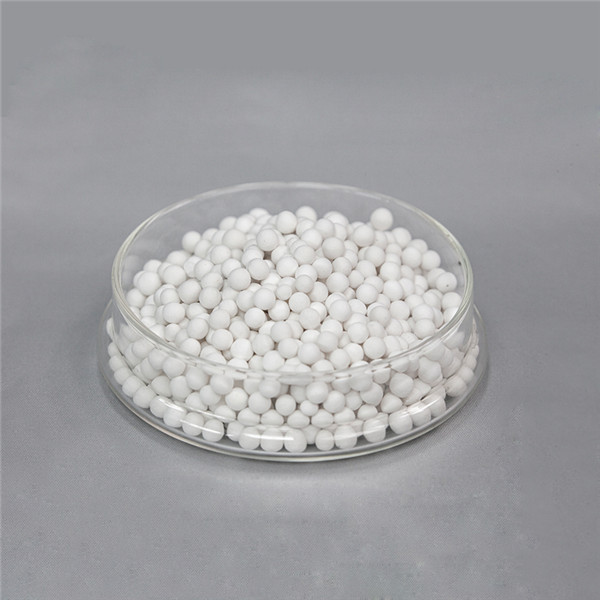

Grinding Balls are suitable for grinding medium used in ball grinding machines.

Technical Parameter

|

Product

|

Al2O3 (%) |

Bulk density (g/cm2 ) |

Water absorption |

Mohs Hardness (scale) |

Abrasion loss (%) |

Color |

|

High Alumina Grinding Balls |

92 |

3.65 |

0.01 |

9 |

0.011 |

White |

|

Appearance Demand |

||||||

|

High Alumina Grinding Balls |

||||||

|

Crack |

Not Permission |

|||||

|

Impurity |

Not Permission |

|||||

|

Foam hole |

Above 1mm not permission, size in 0.5mm permit 3 balls. | |||||

|

Flaw |

Max. size in 0.3mm permit 3 balls | |||||

|

Advantage |

a)High Alumina Content b)High density c)High Hardness d)High Wearing Feature |

|||||

|

Warranty |

a) By National Standard HG/T 3683.1-2000 b) Offer lifetime consultation on problems occurred |

|||||

Typical Chemical Compositions

| Items | Proportion | Items | Proportion |

|

Al2O3 |

≥92% |

SiO2 |

3.81% |

|

Fe2O3 |

0.06% |

MgO |

0.80% |

|

CaO |

1.09% |

TiO2 |

0.02% |

|

K2O |

0.08% |

Na2O |

0.56% |

Specific Properties

|

Spec.(mm) |

Volume(cm3) |

Weight(g/pc) |

|

Φ30 |

14±1.5 |

43±2 |

|

Φ40 |

25±1.5 |

126±2 |

|

Φ50 |

39±2 |

242±2 |

|

Φ60 |

58±2 |

407±2 |

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Quality Inspection for Wear-Resistant Grinding Balls for Wet Ball Mills, Alloy Steel Balls, Our firm is dedicated to offering customers with substantial and secure top quality items at competitive cost, earning every customer contented with our services.

Quality Inspection for China Steel Balls and Grind The Ball, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which might be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.