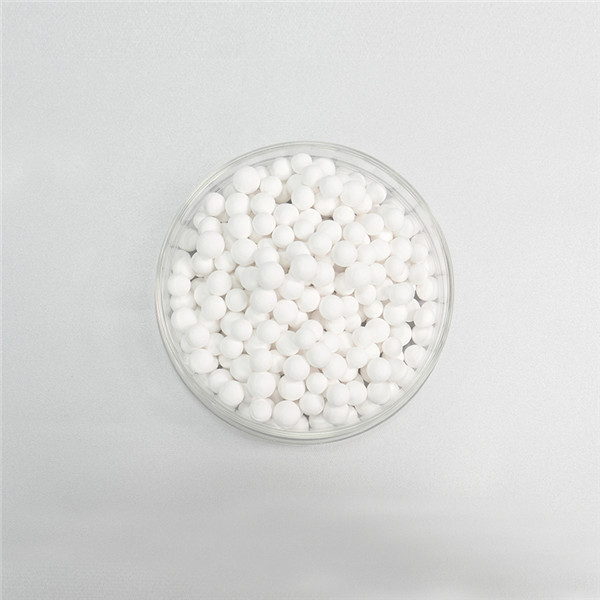

99%AL2O3 Inert Alumina Ceramic Ball – Catalyst Support Media

Application

99% high alumina ceramic balls are widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries as catalyst covering carrier materials and tower packing in reactors. It has high temperature and pressure resistance, low water absorption, stable chemical properties, resistance to acid, alkali and other organic solvents, and can withstand the effects of temperature changes during the production process. Its main function is to increase the distribution point of gas or liquid, support and protect the catalyst with low activity.

Chemical Composition

|

Al2O3 |

Fe2O3 |

MgO |

SiO2 |

Na2O |

TiO2 |

|

>99% |

<0.1% |

<0.5% |

<0.2% |

<0.05% |

<0.05% |

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<4 |

|

Packing density (g/cm3) |

1.9-2.2 |

|

Specific gravity (g/cm3) |

>3.6 |

|

Operation temp.(max) (℃) |

1650 |

|

Apparent porosity (%) |

<1 |

|

Moh’s hardness (scale) |

>9 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

kgf/particle |

KN/particle |

|

|

1/8" (3mm) |

>40 |

>0.4 |

|

1/4" (6mm) |

>80 |

>0.8 |

|

1/2" (13mm) |

>580 |

>5.8 |

|

3/4" (19mm) |

>900 |

>9.0 |

|

1" (25mm) |

>1200 |

>12 |

|

1-1/2"(38mm) |

>1800 |

>18 |

|

2" (50mm) |

>2150 |

>21.5 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |