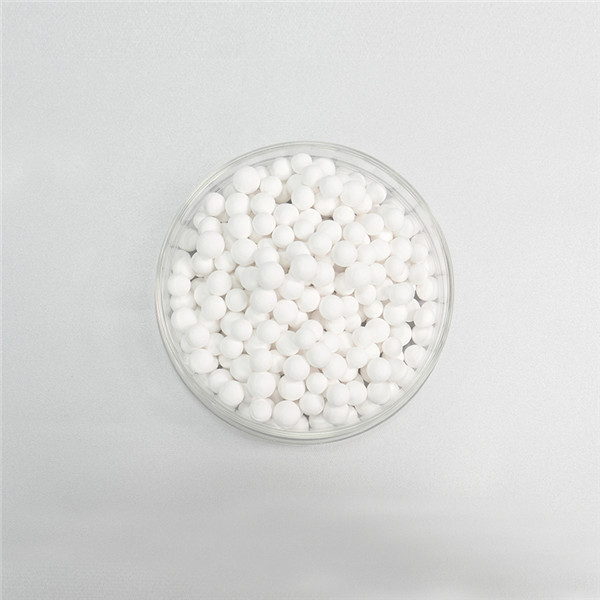

Wholesale Ceramic Ball Support Media - 99%AL2O3 Inert Alumina Ceramic Ball – Catalyst Support Media – Kelley

Wholesale Ceramic Ball Support Media - 99%AL2O3 Inert Alumina Ceramic Ball – Catalyst Support Media – Kelley Detail:

Application

99% high alumina ceramic balls are widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries as catalyst covering carrier materials and tower packing in reactors. It has high temperature and pressure resistance, low water absorption, stable chemical properties, resistance to acid, alkali and other organic solvents, and can withstand the effects of temperature changes during the production process. Its main function is to increase the distribution point of gas or liquid, support and protect the catalyst with low activity.

Chemical Composition

|

Al2O3 |

Fe2O3 |

MgO |

SiO2 |

Na2O |

TiO2 |

|

>99% |

<0.1% |

<0.5% |

<0.2% |

<0.05% |

<0.05% |

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<4 |

|

Packing density (g/cm3) |

1.9-2.2 |

|

Specific gravity (g/cm3) |

>3.6 |

|

Operation temp.(max) (℃) |

1650 |

|

Apparent porosity (%) |

<1 |

|

Moh’s hardness (scale) |

>9 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

kgf/particle |

KN/particle |

|

|

1/8″ (3mm) |

>40 |

>0.4 |

|

1/4″ (6mm) |

>80 |

>0.8 |

|

1/2″ (13mm) |

>580 |

>5.8 |

|

3/4″ (19mm) |

>900 |

>9.0 |

|

1″ (25mm) |

>1200 |

>12 |

|

1-1/2″(38mm) |

>1800 |

>18 |

|

2″ (50mm) |

>2150 |

>21.5 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

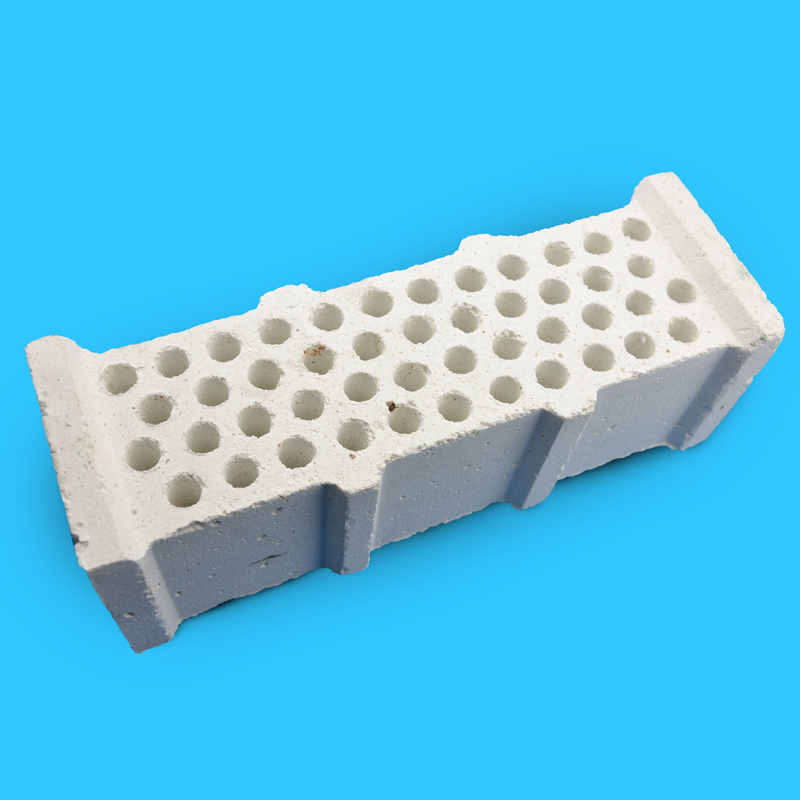

Product detail pictures:

Related Product Guide:

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Wholesale Ceramic Ball Support Media - 99%AL2O3 Inert Alumina Ceramic Ball – Catalyst Support Media – Kelley, The product will supply to all over the world, such as: Peru, Denmark, New Zealand, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.